|

|

|

Mechanical Pendulum Electronic

Control

By:

Bertrand Zauhar, VE2ZAZ

Last updated: 30/05/2015

On this

page, I describe my attempts and successes in

disciplining a mechanical pendulum to an

external 10MHz reference. Short term

accuracies in the order of 1 ppm can be

achieved.

The software source code on this page is

published under the GNU GPLv3 license. Please

refer to the following web site for

more detail on the licence agreement: http://www.gnu.org/licenses/gpl-3.0.html

I have been doing ham radio and electronics

for too many years. I have played and used

electronic crystals and oscillators during all

those years. In parallel, I have always been

fascinated with pendulum clocks. This must

have come from the fact that my parents owned

a 100-year old wall clock. The ticking and

chime sounds filled my childhood space.

A pendulum is one

form of oscillator, a mechanical counterpart

to the electronic oscillator. In that

sense, I wanted to experiment in making a

pendulum more accurate (disciplining) using

electronics, more or less what I had done in

the crystal oscillator world with my GPS-Derived

Frequency Standard.

So this page details the evolution of this

project. It also presents the final

implementation and offers the software to

those who would like to be inspired in doing

the same. As such, this is not offered as a

plug-and-play solution; but rather some

description to inspire others.

The first thing

I did was to read on the internet. I

strongly suggest you do so. This will

actually trigger some more interest. I

recommend you read Tom Van Baak's LeapSecond.com

website. In particular, the "Precision

Pendulum Clocks, Gravity and Tides"

section, which was an inspiration to

me.

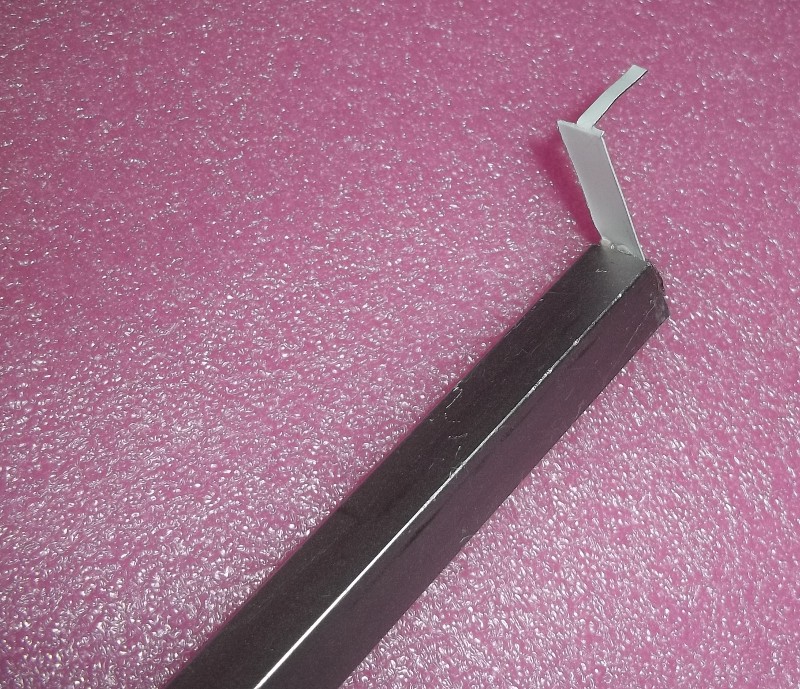

My first objective was to build a

simple mechanical pendulum, using what

I had on hand. I recovered a Hard Disk

Drive (HDD) seeking head ball bearing,

which is what I still use today.

Those are very well made and will

obviously last for a long time... I

also took a 1.2 meter long, 12 mm

square aluminium tubing. For the

weight, I used a clamp -on lead weight

normally sold to pull back the hand

shower hose of kitchen faucets.

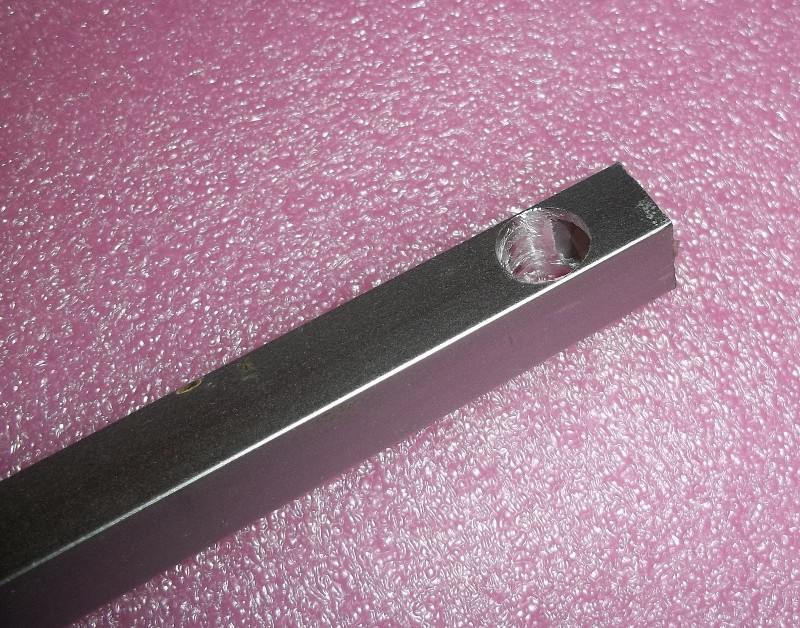

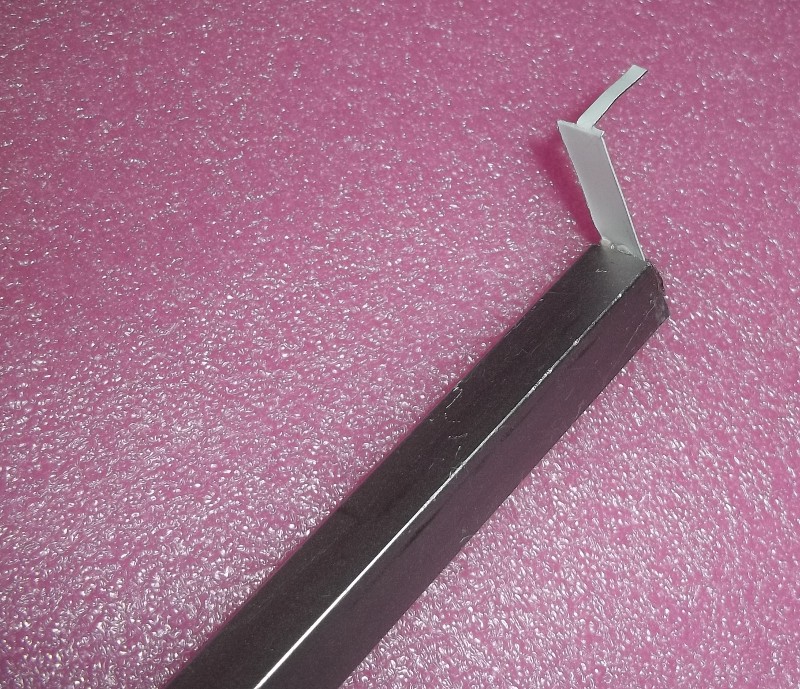

At the bottom end of the tubing, I

added a needle made of thin aluminium

flashing. This would trigger an

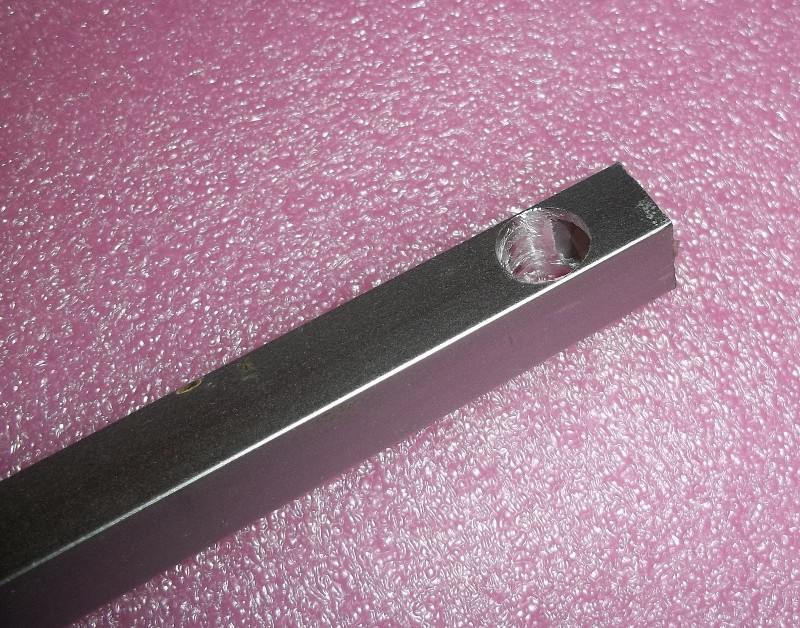

opto-detector. At the top end of the

tubing, I drilled a hole of the right

diameter to snug-fit the HDD bearing.

I also made a bracket to support the

pendulum via the bearing screws.

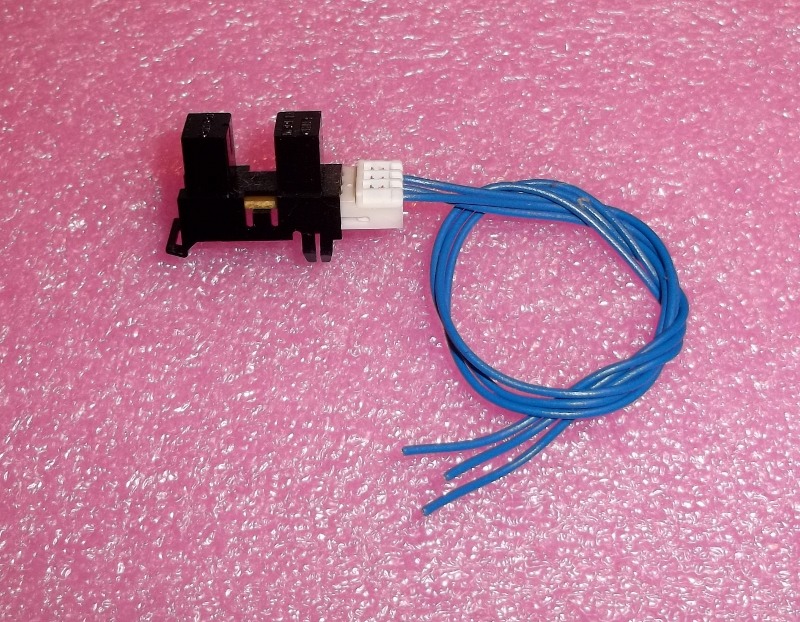

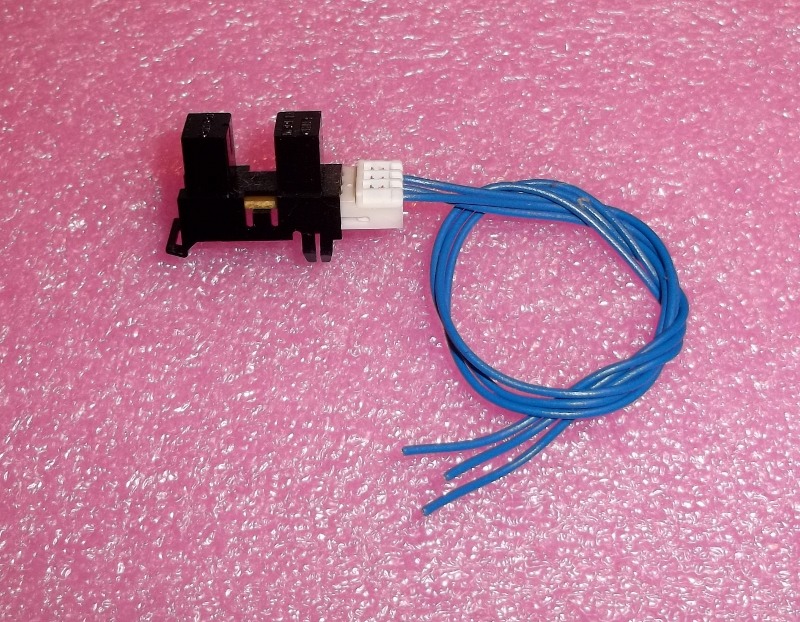

That opto-detector was recovered from

an old ink-jet printer. I applied a 5

mA DC bias on the LED and wired the

photo-transistor to a universal

frequency counter.

To support the pendulum, I used a

C-clamp to fix the attachement bracket

to the top of a 1.5 meter tall 19"

electronics rack. Obviously, the rack

had to be very stable so that little

energy would get dissipated by the

rack.

|

Aluminium Arm Needle

Arm Bearing Hole

HDD Bearing

Opto-Detector

|

This above setup allowed me to measure the

period of the pendulum, and adjust the height

of the weight to reach very close to a two

second period (actually a pulse every second,

but I skipped one pulse because the time it

takes to trigger the opto-detector on either

sides of the pendulum swing will not be the

same if the opto-detector is not positioned

exactly in the center of the pendulum swing).

The first finding was that this thing swung

smoothly. In fact, it swung so smoothly that

it was still oscillating a bit after 20

minutes, for a initial swing amplitude of

about 5 degrees of angle. That HDD bearing is

good! That setup looked promising.

The second finding, looking at the frequency

counter readings, was that the period varied

slightly as a function of the swing amplitude

(angle). This confirmed the theory, that there

are external factors that make the period go

longer with an increased oscillation

amplitude. This phenomenon confirmed my plan:

To design a system that adjusts the swing

amplitude to correct for time inaccuracies and

keep the pendulum locked to an external

reference.

The following experiment

was to periodically introduce some energy

into the system to compensate for the loss

of energy due to friction (air, bearing,

etc). For this I glued a small refrigerator

magnet to the end of the pendulum arm. I

also positioned a coil recovered from a DC

mechanical relay right below the magnet,

with the coil's magnetic field axis in the

same orientation as the pendulum arm. This

made the coil attract the magnet vertically

and downward when the pendulum was at rest.

With this kind of setup, one must energize

the coil only for a known

short duration,

otherwise the attracting force will slow

down the pendulum when passing beyond its

vertical point. this called for a pulsed

energy coil triggered by the opto-detector.

A 555 timer IC and pass transistor did the

trick. The 555 would energize the coil for

some adjustable duration when the

opto-detector has its light beam interrupted

by the needle.

First finding: That setup usually worked for

some time, for a few hours, but the pendulum

would often stop overnight. Clearly, there

were external factors that unbalanced the

system.

Second finding: Temperature had a

significant effect on period. So much that a

static setup like this one, with constant

impulse duration, would eventually die when

the pendulum is submitted to one or two

degrees Celsius of temperature variation.

This variation being typical of a heating

cycle on any central heating (furnace), a

dynamic pulse duration adjustment would be

required to maintain and regulate pendulum

oscillation.

Third finding: This behavior is mostly due

to the pendulum arm's thermal expansion.

Aluminum is one of the worst materials there

is in terms of thermal expansion. Clearly, a

better material should be used. See Wikipedia

for more detail on that topic.

I knew that, ultimately, I would be using a

micro-controller to "disciplin" the

pendulum. But I happened to have a Raspberry

Pi computer board on hand. I thus

decided to use it and quickly produce some

software to control the coil impulse

duration as a function of oscillation

period. I elected to use Python as the

programming language since I was quite

comfortable writing code in it. I had one

main concern, the real-time behavior of that

computer running a Linux operating system.

One asset I had used before is the RPIO

library of Python functions. It includes

some neat hardware interrupt management

routines.

The goal was to replace the 555 timer IC

with the Raspberry Pi's variable pulse

length. The operation consisted in:

1 -

Capturing the period via the opto-detector as

quickly as possible as soon as the pulse comes

in on one of the GPIO pins. Use the computer

clock to compute the period.

2 - Doing an averaging over 10

period readings to reduce the amount of

variability in the reading.

3 - Calculating a new coil pulse

width based on the average period:

Increase pulse width if

period is too short,

Decrease pulse width if

period is too long,

4- Sending the pulse as soon as

the needle comes out of the opto-detector

area.

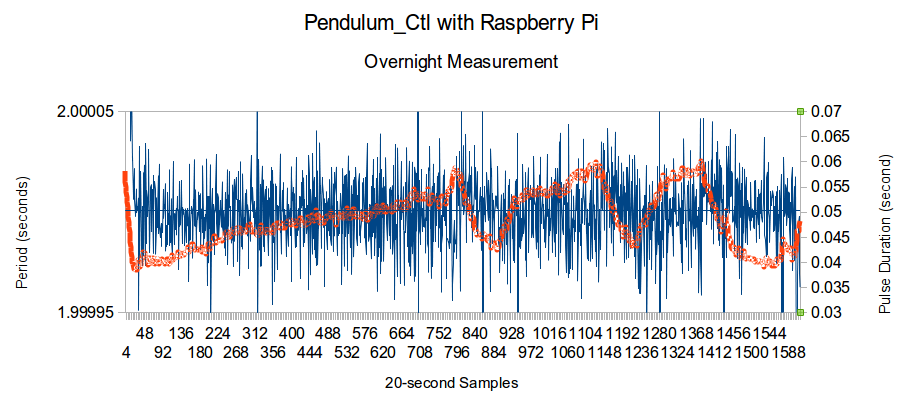

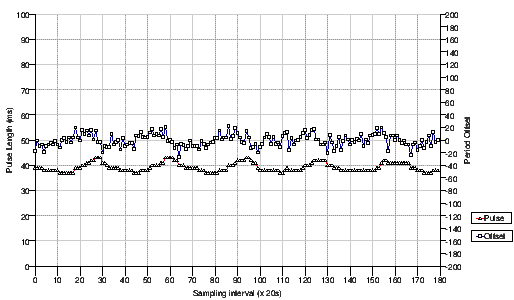

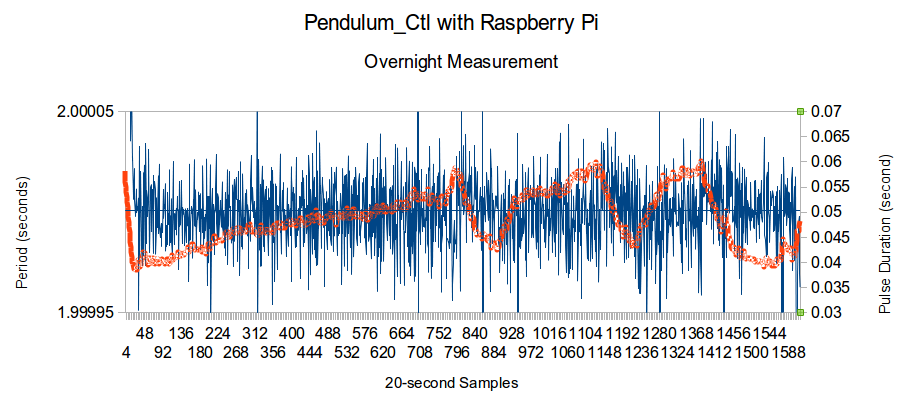

The

operation ended up being quite functional and

useable. The following plot shows a

winter-time overnight indoors measurement.

From this graph,

the following observations can be made:

- There is no measurement

of phase being done, merely a period

(1/F) measurement. Thus this is a

Frequency-Locked-Loop system (FLL),

not a Phase-Locked-Loop (PLL). We

should probably call it a

Period-Locked-Loop...

- There is a clear

compensation action for temperature

variations. The red curve shown the

variation of the coil pulse width due

to overnight temperature variations.

One can actually correlate the

behavior with the home heating system

cycles: At 22:00 (on the left) the set

temperature is brought down by a

couple of degrees C. This generates a

slow and long decline of the pulse

width to compensate for the shortening

of the pendulum arm. Starting half way

into the night, a couple of 1-degree C

heating cycles can be seen. In the

morning, a longer heating cycle occurs

to elevate the temperature back to 21

C. This overnight behavior was very

rewarding to see.

- Even with the raspberry

Pi's non-real-time operating system,

we can clearly see that measurement

and control of a pendulum is possible.

From that graph, we can say that a

short term accuracy of around +/- 25

PPM can be achieved. Not bad. But a

PIC micro-controller sampling a 10MHz

reference clock should do much better

in terms of accuracy and resolution.

Pendulum_Ctl.py

At this point, I

had enough information to implement a much

better system. Here are the specifications

I wanted to meet.

- The accuracy had to be

much better than the one achieved with

the aluminum arm and the Raspberry Pi,

with an reasonable objective of not

being worse than +/- 1ppm for a

10-sample period.

- The system would have to

be housed in a temperature-regulated

enclosure.

- The pendulum arm would

have to be made of a less temperature-expanding

material.

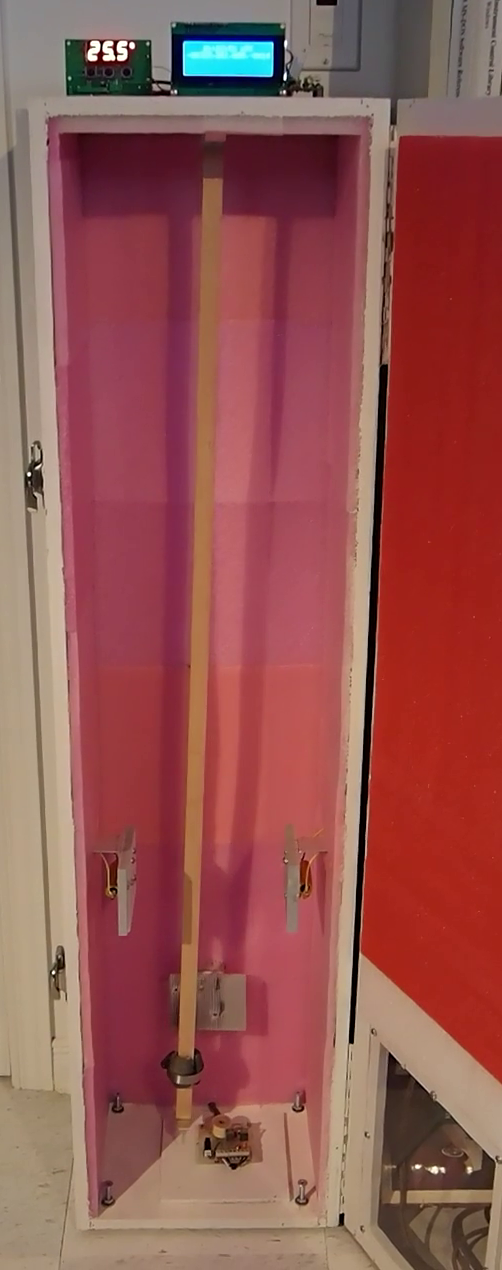

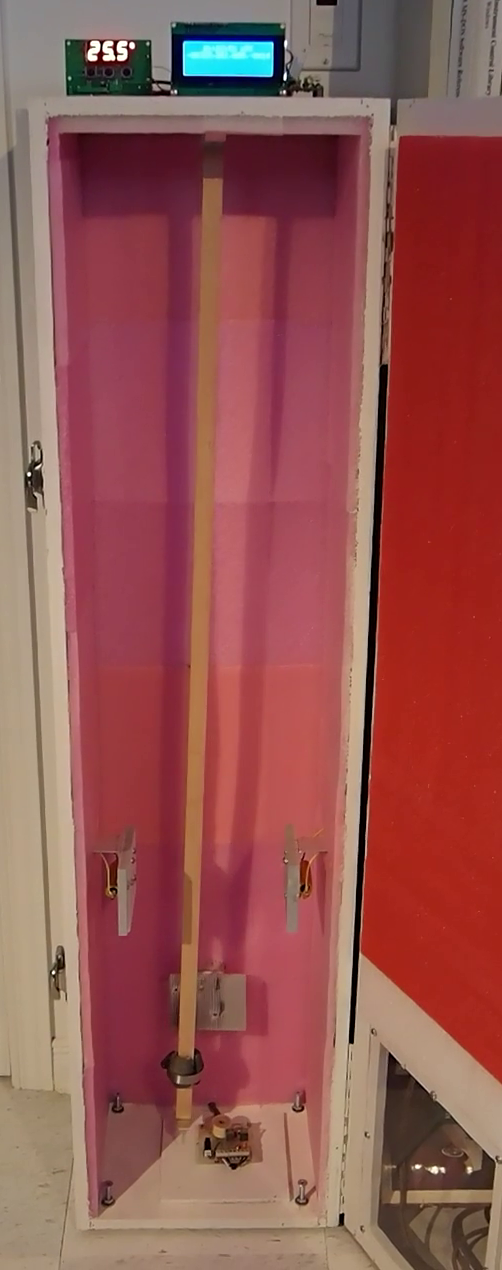

Pendulum

Arm Material

After consulting the

literature on thermal expansion

coefficient of various

materials, and since

CoVar and InVar are too pricey, I

decided to use wood: I happened to

have a strip of oak wood, with longitudinal

wood grain. It was a 1" (25 mm) square

piece from which I shaved off 50%

total on 2 sides, in an attempt to

reduce the arm weight and friction

in the air. The end-result is a 1"

by 1/2" (25mm x 12mm), 45" (1.15m)

long arm. |

|

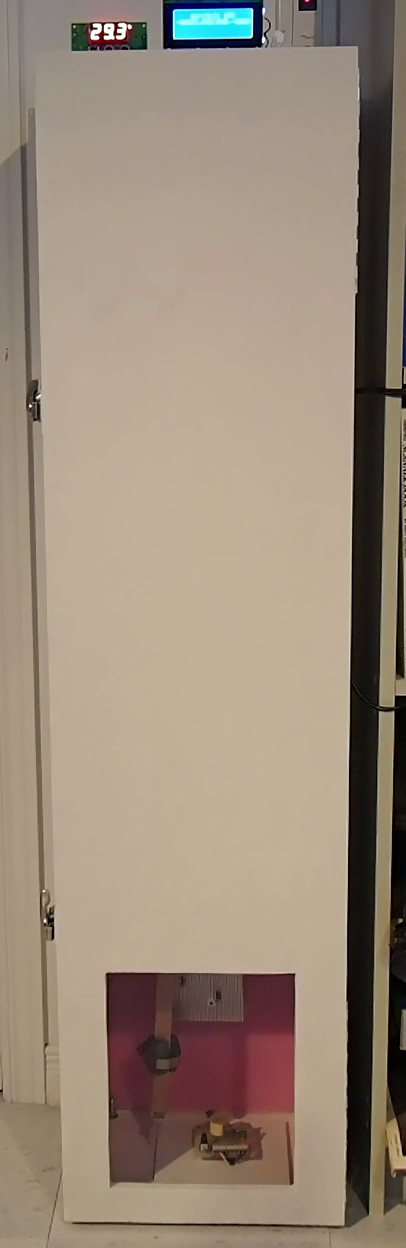

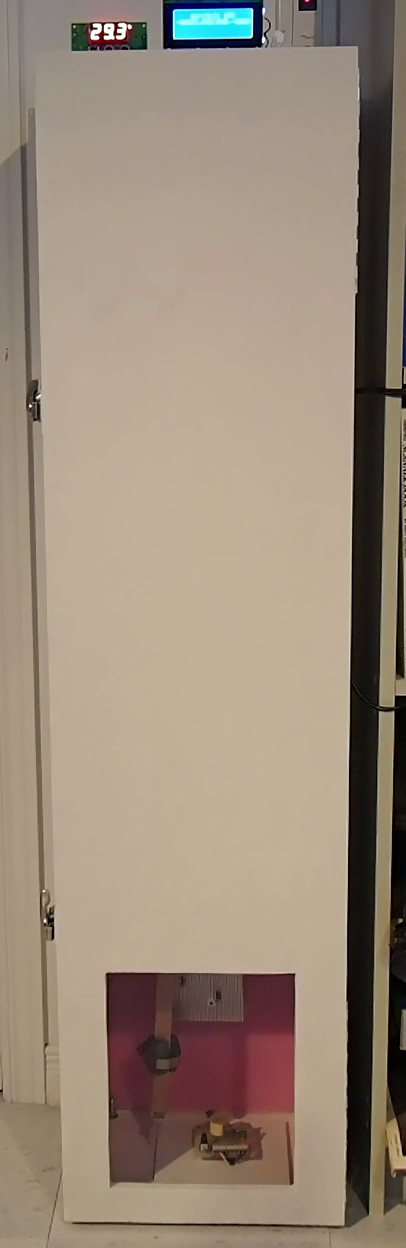

Enclosure

I built a 48" tall x 12" wide

x 9" deep (122cm x

30cm x 23cm), 1/2" (12mm) thick

plywood enclosure. I included, a

door, door latches, hinges and a

plexiglass window at the bottom of

the door. I insulated the interior

using some pink foam, the type

used in the shipping of

electronics. This is not the

typical cushion air foam, rather a

dense, air-tight, air-filled

matter. See one of the pictures

above for a close-up view of

the foam. The enclosure has

adjustable feet (pegs) to allow

for level and stability adjustment.

Environment control

The

enclosure is heated up to 30

degrees Celsius, which I consider

to be a higher temperature than

the ambient temperature will ever

reach. In order to heat up the

inside, I use three 100 Ohm, 50

Watts power resistors connected up

in series on the 120 VAC mains.

This represents a heating source

of around 45 Watts. The resistors

are mounted on three separate

aluminum heat sinks mounted

symetrically inside. The heating

are controlled by a temperature

controller (a fancy thermostat, I

guess) via a power Solid State

Relay. The mains is fused at 1

Ampere. This controller starts the

heating at 29.5 oC and stops it at

30.0 oC. I wish I could find a 0.1

oC controller for cheap. I guess I

will have to design it!

FLL control

I elected to port the FLL

firmware over to a PIC12F683

micro-controller. This is an

8-pin, sub-dollar, powerful

micro. The firmware does

essentially the same as on the

Python script described above.

It also sends a serial data

string containing the raw

information (measured period,

average period, current pulse

duration) so that further analysis

and plotting can be made on a

personal computer. The PIC firmware

Ansi-C source code is offered

here as inspiration for similar

setups.

Pendulum_Ctl.c

A stable timing

reference had to be

introduced in order to

increase period

measurement accuracy. I

use an on-board 10 MHz

Temperature-Compensated

Crystal Oscillator

(TCXO) as the reference

for incrementing the

internal PIC 16-bit

counter. I also provide

the ability to inject an

external 10MHz reference

signal through an

LTC1485, which

scales up the signal

to a 5V TTL swing.

For ease of interfacing with

the 4x20 HD44780-compatible

LCD module, I programmed a

separate PIC12F683

micro-controller to manage the

LCD display. It receives the

same data string from the FLL

Control PIC, formats the data

and sends the display commands

to a Digole

Universal Serial LCD Display

Adapter board. This board

eases LCD control using some

simple one-wire serial

commands instead of the more

complex HD44780 multiple

control line handshaking. Here

is the LCD PIC Micro source

code:

|

|

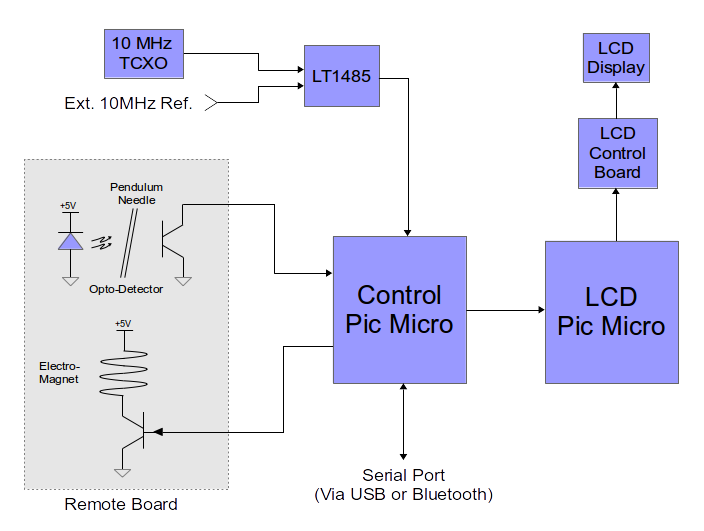

The electronics are mounted on

two custom-made printed circuit boards

(PCBs). The following simplified block

diagram shows the various functions

implemented.

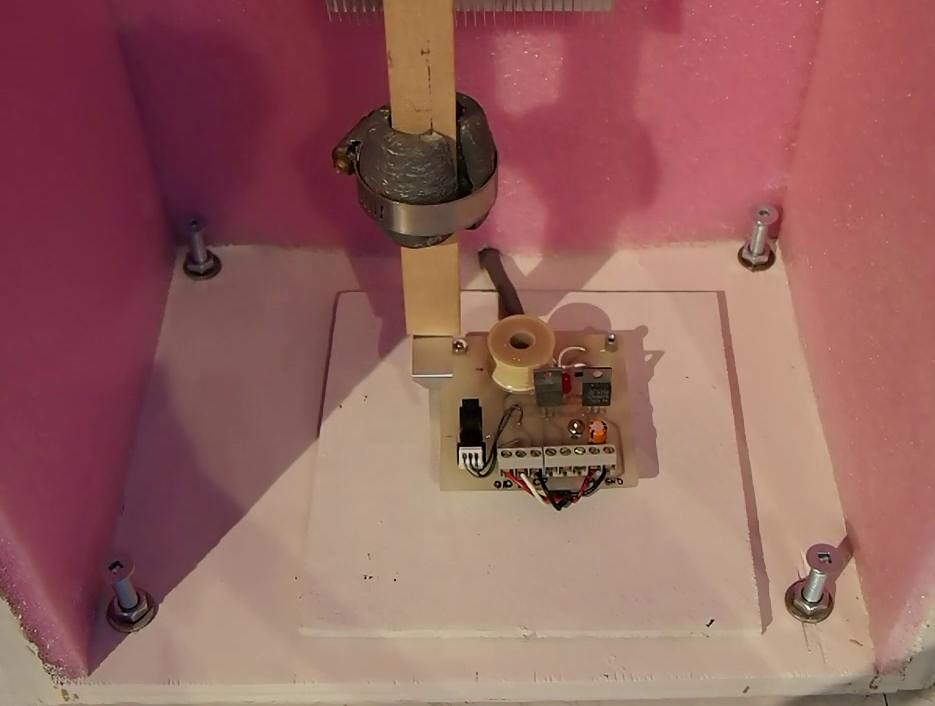

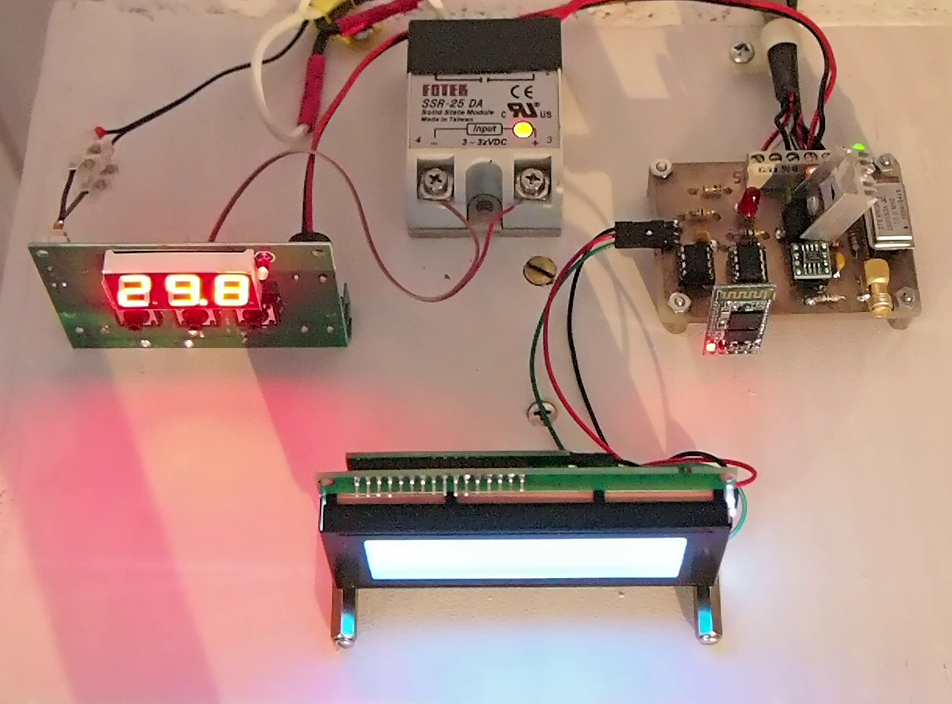

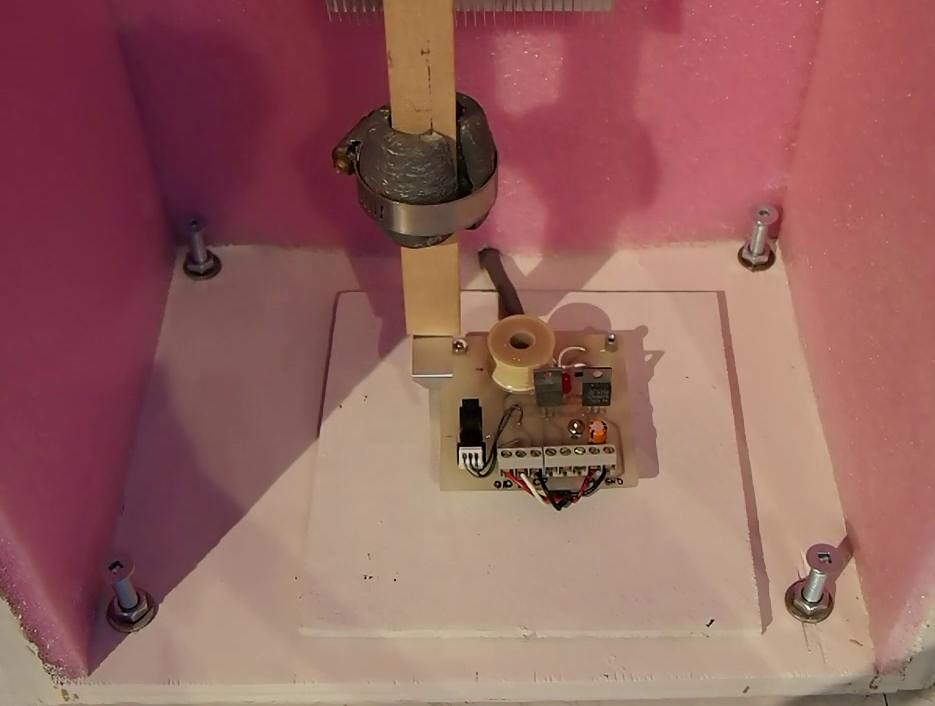

Here is a top view

of the FLL control hardware and the

temperature control hardware.

Here

is a top view of the remote control board

and lower end of the pendulum inside the

enclosure.

Results

Once the system is running stable at a

regulated temperature (~ 0.7 oC

variations), this is what you get:

- The

horizontal scale shows sampling

intervals of 20 seconds. Each point

is an average of ten

2-second pendulum periods. The graph

shows a one hour duration.

- The

top curve represents the period

offset from 2.0000000 seconds,

represented as 10.000 MHz counter

increments. In one 2-second pendulum

period, you would expect to counts

20,000,000 increments, and this

shows how many increments the offset

represents. In other words, 20

increments is a one part-per-million

offset.

- The

bottom curve represents the

electro-magnet pulse duration,

expresses in milliseconds. On this

graph, the pulse duration runs at

around 40 ms.

The

take-aways from this graph are:

- FLL

action is effective, as we can see

electro-magnet pulse length

adjustments to compensate for

temperature variations in the

enclosure. There is still a bit of

temperature variation ripple seen on

the top curve. I wish we could see a

perfectly flat top curve; this would

show perfect FLL action, but this is

not easily achievable. FLL

parameters can be tweaked but this

is a balancing act. You do not want

to over-compensate either or you

will lose "lock" and/or have a hard

time locking up again. Also, there

is lag due to averaging that it has

to deal with.

- The

top curve essentially stays within

the +/- 1 ppm band (+/- 20 counts),

which meets my initial objective for

ten-sample averaging. To put

everything in perspective, 1 ppm is

one microsecond out of one second.

Not bad for a mechanical pendulum!

Of course, on the long term, the

system will average out to much

better than that, as it will always

tend to center on the nominal 2

second period.

- Temperature

regulation to 0.5 oC is still

not great. I wish I had a 0.1 oC

regulation. I guess this will be

my next project... Challenging

if you consider the level and

stability of small signals to

measure.

- The PIC-micro counter-based

FLL approach is a much better

technique than the software-driven

Raspberry Pi clock. We got a +/- 25 ppm

on the Pi, and we get +/-

1 ppm with the PIC.

A

few more observations to make:

- Walking by

the enclosure, even

carefully slowly, is

noticeable if the enclosure

is not installed on a

concrete floor. In my

basement shack, where

development took place, I

have a raised floor made of

1/2" plywood. This is enough

to transfer vibration to the

pendulum. The graph to the

right illustrates this, with

the FLL bringing the

pendulum back where it

should be.

|

|

- My

original temperature controller used

a mechanical relay to turn on/off

the heating. This caused a lot of

noise on the period readings. I

simply disconnected the relay and

used its control voltage to operate

the solid state relay. Problem

solved.

I

produced a Youtube

video that shows many details and

provides additional information on

operation.

|

|