|

|

|

Stability

and

Accuracy

Improvements

to

the

HP 3586A/B/C Selective Level Meter SSB Audio

By:

Bertrand

Zauhar, VE2ZAZ

Page last

updated: 22/04/2011

This

page presents a modification to the Hewlett-Packard 3586A/B/C SLM

(receiver) BFO circuit that makes the entire SLM referenced to the

10MHz source, whether internal or external. This removes any SLM

receiver drift due to temperature. After the mod is performed, any

drift detected while making SSB audio tone

measurements external to the unit will not have the SLM drift embedded

into the measurements.

Good for FMT measurements! A

few hours of work and $25 or so will put you and keep you on frequency.

The HP 3586

Selective Level Meter (SLM)

is a great piece of test

equipment. It is a super HF receiver with lots of measurement bells and

wistles. One drawback of this equipment though is the fact that one of the mixing stage

LOs

is not derived from the on-board or externally fed 10MHz reference. The

last stage, the product detector has its BFOs (LSB, USB) free running

using regular quartz crystals. Unfortunately these drift. The drift is

insignificant and non-perceivable if you only listen to the SSB audio.

But if you perform long term tone frequency measurements, this is a

show stopper.

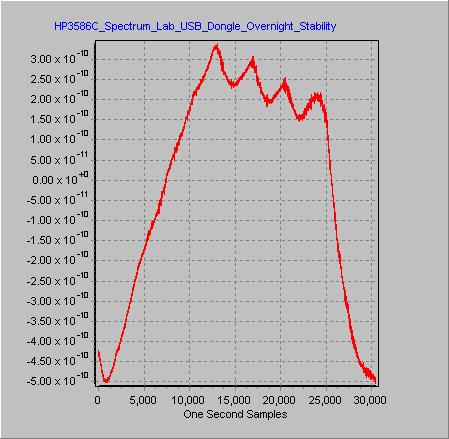

The plot below shows how much SSB BFO drift I detected using a stable

carrier fed into the RF input of the SLM. The audio tone produced by

the carrier was measured on a PC sound card using Spectrum Lab

software. This drift was caused by day-night-day variations in room

temperature. This was induced by a variation of around 2 degrees

Celcius. You can actually see the house heating system's behavior, with

a major night time reduction of temperature, a few heating cycles

overnight and a temperature recovery phase in the morning. Note that

the sound card drift was also measured, but it can be ruled out as a

major contributor in this plot since it drifts in the opposite

direction as a function of temperature.

So how

to improve this great test instrument and make it rock-solid? Here is

what I did.

The HP 3586 SLM uses two or three SSB LO frequencies internally,

depending on the model. They are the USB, LSB and Calibration

Mode frequencies. These frequencies vary as a function of the unit

model and

the equipped options. Here is a table extracted from the Service manual

that summarizes the various configurations:

HP 3586 Single

Sideband (SSB) L0 Frequencies.

|

| Model |

Opt. 003 |

Cal Active |

Bandwidth |

Sideband |

Crystal |

Crystal Freq. |

SSB L0 Freq. |

| 3586A/B |

YES |

NO |

3100Hz |

USB |

A22Y102 |

1.7475MHz |

17.475kHz |

| 3586A/B |

YES |

NO |

3100Hz |

LSB |

A22Y101 |

1.3775MHz |

13.775kHz |

| 3586A |

YES |

YES |

3100Hz |

- |

A7OY1 |

1.6425MHz |

16.425kHz |

| 3586B |

YES |

YES |

3100Hz |

- |

A7OY1 |

1.6625MHz |

16.625kHz |

| 3586A |

NO |

NO |

1740Hz |

USB |

A22Y102 |

1.6975MHz |

16.975kHz |

| 3586A |

NO |

NO |

1740Hz |

LSB |

A22Y101 |

1.4275MHz |

14.275kHz |

| 3586B |

NO |

NO |

2000Hz |

USB |

A22Y102 |

1.7125MHz |

17.125kHz |

| 3586B |

NO |

NO |

2000Hz |

LSB |

A22Y101 |

1.4125MHz |

14.125kHz |

| 3586C |

- |

NO |

3100Hz |

USB |

A22Y102 |

1.7475MHz |

17.475kHz |

| 3586C |

- |

NO |

3100Hz |

LSB |

A22Y101 |

1.3775MHz |

13.775kHz |

So the proposed solution has to be

reconfigurable on-the-fly, as the SSB mode is selected by the user via

the front panel pushbuttons and

when the Calibration state is invoked by the unit's firmware. It also

has to be flexible enough to accomodate the various SLM versions.

The Analog Devices AD5932

is a great little chip. It is a DDS-based Programmable Frequency

Waveform

Generator fitted inside a TSSOP 16-pin package. This chip has a

frequency divider with 224 steps. This means you can put out a

clock with a division resolution of 224 steps applied to the input reference

clock. What you also need is an accompanying chip to load the AD5932

with the right configuration at power up or when the SLM SSB mode is

changed. An 8-pin PIC12F683 is perfectly suited for this task.

Except

for the 10MHz clock reference, all

input and output signals to the proposed circuit are 5V-TTL logic, so

this is

a simple interface to the HP 3586, with a 5 VDC supply applied to both

the AD5932

and

the

PIC

micro.

The

10MHz

reference

signal

needs

a

bit

of

waveform

amplitude

and offset

scaling to make it a TTL-compatible clock; that can be perfromed by a

single NPN

transistor. Both chips and the transistor fit on a small add-on PCB that connects to

various points within the SLM.

Here is a block

diagram that shows how this solution is implemented inside the HP 3586

SLM.

Here is a schematic

diagram of the proposed add-on circuit. Click

on the figure to see it in full size.

Inside

the HP 3586 SLM, almost all connections are made to module

A22, one of the plugins inside the unit. Here is a schematic page

extracted from the HP 3586 Service Manual that shows the required

hookups of the above circuit to

module A22. The annotations in red and pink are all there is to it as

far as the SLM itself. Click

on the figure to see it in full size.

The diagram above

also shows the A22 board layout on the left hand side, which will be

helpful to perform these

mods.

I have elected to

extract the 10MHz reference signal that drives the DDS chip directly

from the A40 plugin (the reference plugin) 10MHz output port normally

connected to the rear panel. In my case I don't need the 10MHz output

signal since my SLM does not have the OCXO option.

There are other locations within the SLM where a 10MHz reference could

be tapped off. These other points all use the PECL logic technology.

Consequently, a re-configuration of the 10MHz transistor circuit would

be required. Though I have not tried it, the following circuit would be

a better alternative when dealing with PECL logic swing since it has a

smaller swing. This is essentially a gain stage, with a gain of -5. Consider this circuit as just a

starting point; you may have to tweak the resistor values to center the

DC bias to the PN junction operating range.

I would appreciate

hearing from those who try the PECL avenue. I could update this page

with the information.

Note that

this upgrade

to the SLM has no impact to the built-in frequency and amplitude

measurement capabilities and specifications. This mod only affects the

product detector and the resulting SSB audio.

|

PERFORMING THE A22

PLUGIN PREPARATION WIRING

|

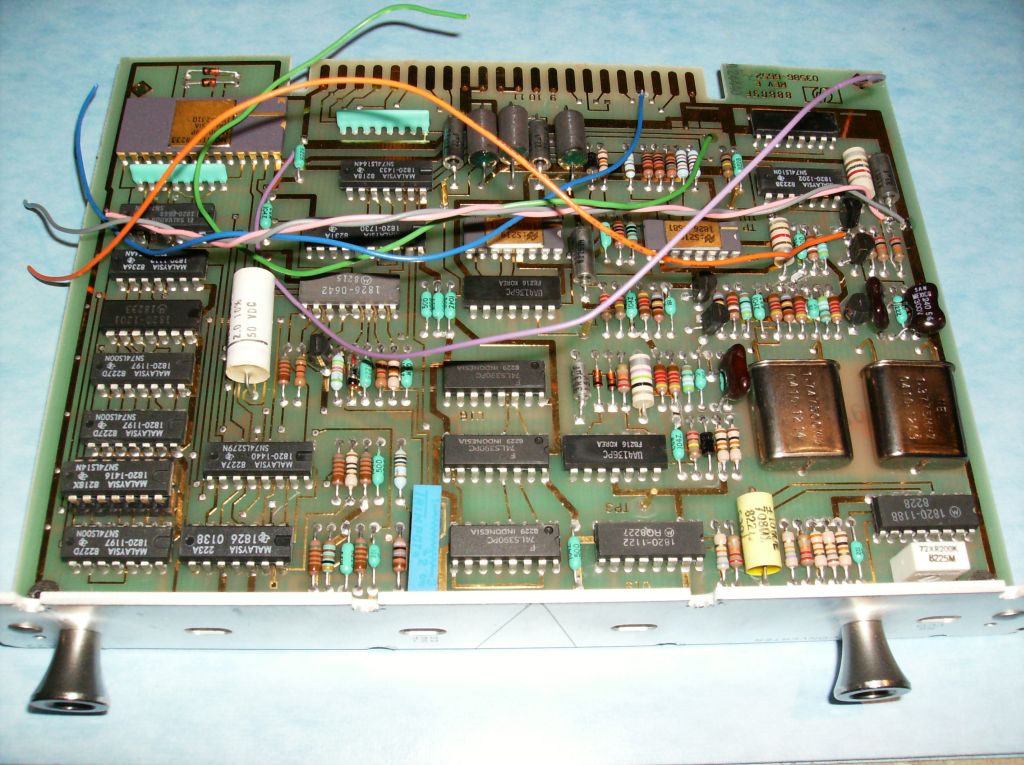

Here are two

pictures showing the wiring work required in preparation for receiving

the add-on board on the A22 plugin. Click

on the figure to see it in full size.

The following are a few instructions and notes that should be taken

into account when performing the mods on the HP 3586 A22 plugin card.

- One the picture above, please disregard the

blue wire. This was added for previous experimentation of this circuit

and is not required anymore.

- Working form the top of the 3586

unit, cover removed, you must remove the eight screws on the A22

faceplate, then pull out the plugin using the two knobs.

- All

added

wires

but

one

are

soldered

to

the

component side of A22.

- The

Axx row of card edge fingers is on the component side of the plugin

PCB, the Bxx row is on the solder side.

- On the solder side of the A22 plugin,

perform a cut on the trace that connects to card edge

finger B2. Use a sharp exacto knife. See solder side picture above

(upper-left corner).

- Again

seen on the solder side picture above, the purple wire is the MSBOUT

signal and it must be soldered to the solder side of the PCB,

and routed to the component side through the nearby hole. That wire may be

connected to card edge finger B2 or to the trace downstream from the

trace cut and toward card edge finger B2. If connecting to the

finger, make

sure you solder the wire to the very edge of

the finger, keeping in mind that the fingers get inserted into the A22

motherboard edge connector. I used kapton tape to keep the liquid

solder from envading the entire finger and contaminate the gold

plating. Refer to the picture above. If connecting to the trace,

you will have to scrape

off the solger resist to expose some copper.

- The

Cal Mode signal, shown as a green wire on the picture above, is only

used on the Option-003-equipped SLMs. Disregard otherwise and leave

unconnected on the PIC.

- This

Cal Mode signal can be

connected to the trace via hole shown in the picture. Follow the trace

from the card edge

finger B15 (solder side) to locate the via hole where to solder to on

the component side.

Note: It appears that there exists a

second version of the A22

board. There are major omponent differences and the board does

not look the same when comparing to the pictures above. Though I have

not seen a board of that other version, there is another version of HP

3586 circuit schematics that details it. If you happen to have one of

these different A22 boards, please communicate to me the changes you had to make to adapt my

mod to the other A22 board version. I will update this web page. Thanks.

|

ASSEMBLING

AND

MOUNTING

THE

ADD-ON

BOARD

ON

A22

|

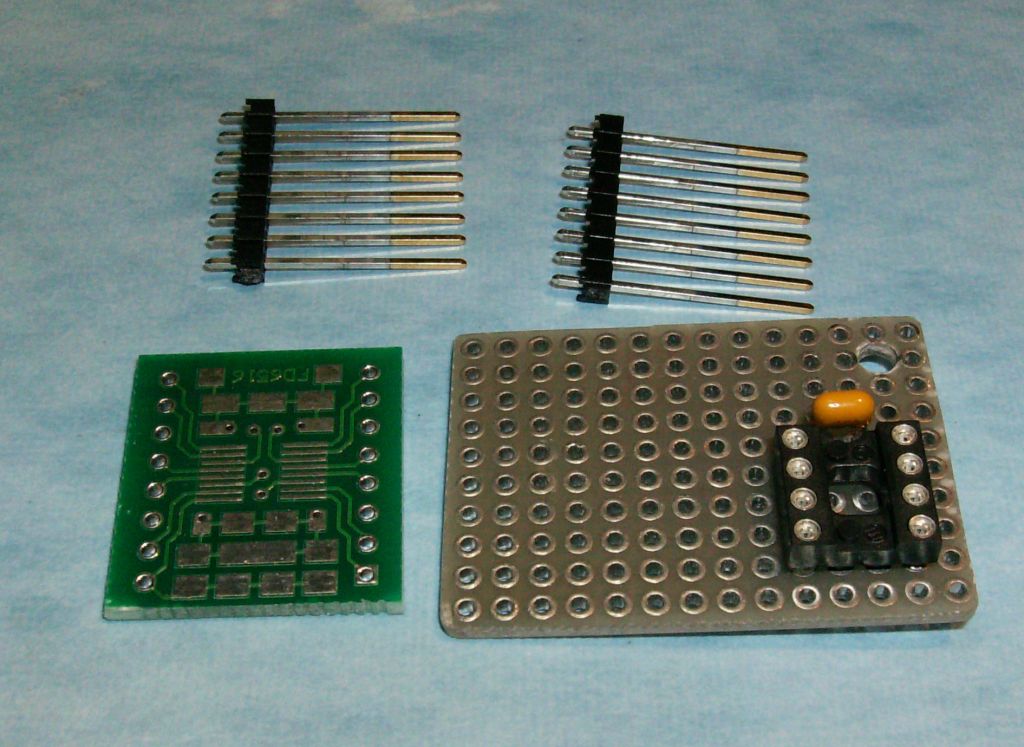

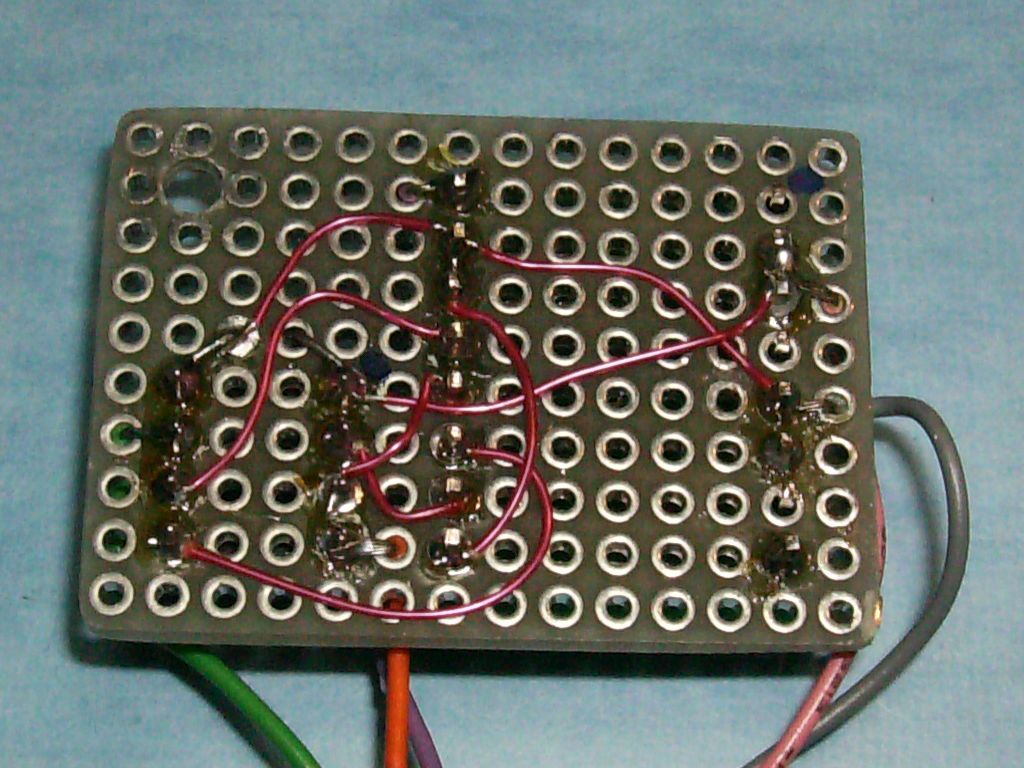

For this stage, there is more than one

option; mine is one suggestion, but you may adapt it based on the

availability of the PCB material or your junk box.

My add-on board is made of two PCBs, a prototype PCB and the TSSOP chip

carrier PCB. The former is a piece of plated-through prototype PCB. The

latter is a ready-made adapter board I purchased on eBay for a few

dollars. Searching for "SSOP DIP adapter" on eBay will yield several

solutions. Hobby electronics components websites are also a good place

to look for these.

Here are a few pictures showing how I put the add-on board together.

My TSSOP carrier PCB has extra pads to

install additional discrete components. With a bit of

planning, I could place all surface-mounted resistors, capacitors and

the transistor on

the TSSOP carrier PCB.

- I used parts of a 0.1 inch header strip

to mount/connect the TSSOP carrier PCB to the prototype PCB. I

suggest

you

first

solder

the

AD5932

chip

onto

the

carrier

PCB before soldering the header pins and the

other components. This gives

access from all angles for the soldering procedure.

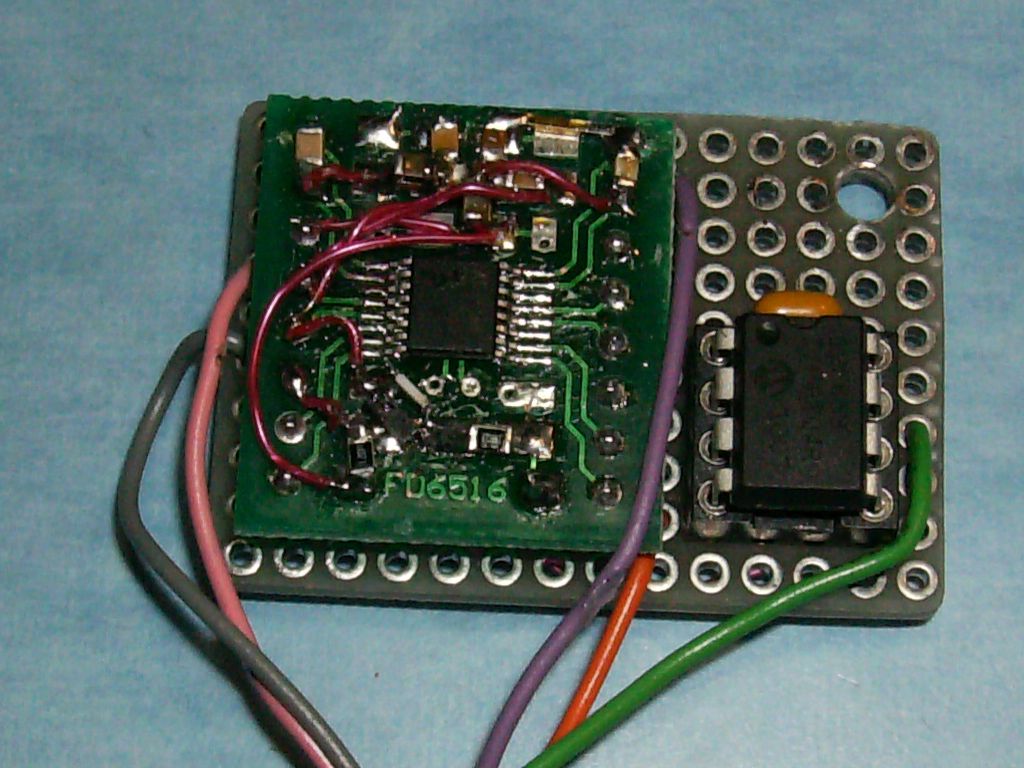

- Soldering the AD5932 chip to the

carrier PCB is not an easy task and it requires skill, steady hands and

the right soldering iron, using the finest tip there is. Hot air

soldering is also possible if the pads are pre-tinned or if using

solder paste. In all cases, use liquid rosin flux to help the soldering

process. A good microscope or stereoscope is mandatory; a magnifying

lamp is not enough unfortunately. If you have not done this in the

past, ask a friend who has done it before for help. It may also be the

right time for you to consider upgrading your soldering/re-work tools...

- I used

(AWG-30 size) wire-wrap wire for the interconnects between the chips. I

strip both ends of their insulation and solder the wires to the pins.

- On

the

A22

plugin, I used the remaining corner mounting hole to install a

standoff post. I mounted the add-on board to the standoff. It keeps it

in a fixed location, away from the A22 components. Make sure that the

final assembly will fit back into the A22 compartment without causing

any short circuit. Notice that there are a few components mounted on

the motherboard inside the A22 compartment. The positioninng and size

of the final add-on board has to clear these components once the A22

plugin is fully inserted.

- Make

sure

there is not too much air

flow restriction as a result of the add-on board presence. The cooling

air is forced from the bottom of the SLM into the A22 compartment

through a few holes in the motherboard.

Here

is a picture of

the completed modification to the A22 plugin.

|

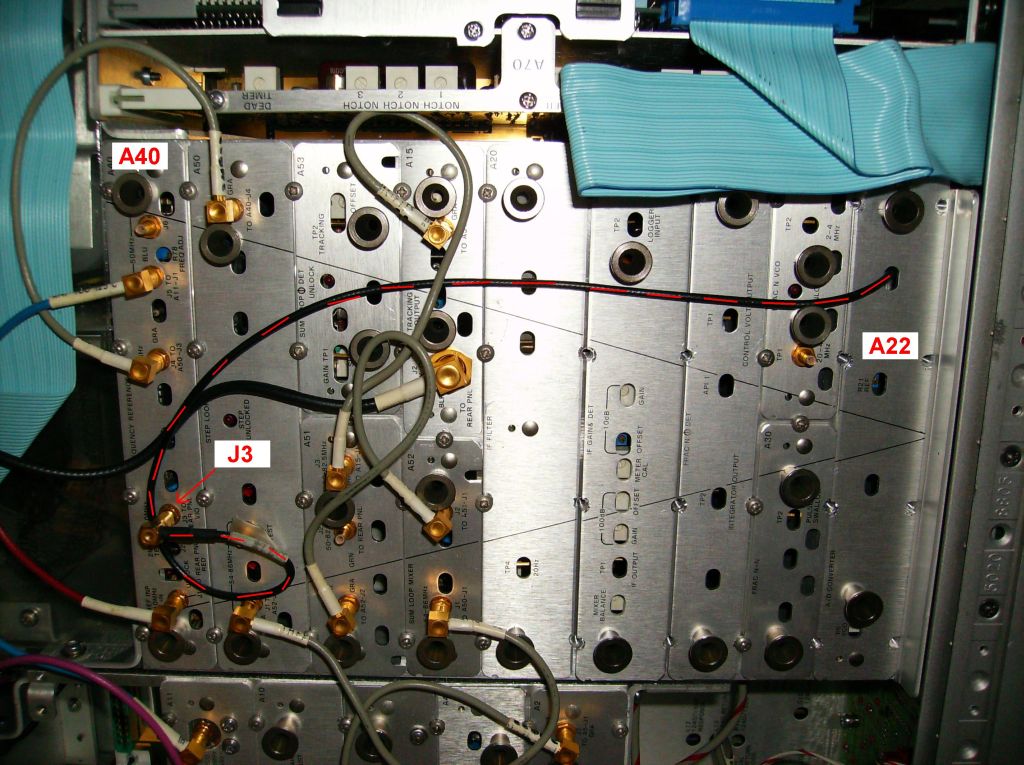

CONNECTING UP THE

10MHz REFERENCE

|

- Disconnect the

SMB coaxial cable

from port J3 on the A40 plugin faceplate. Connect a new coaxial cable

with a SMB connector at one end to J3.

- Route the new

cable towards the A22 plugin.

- Pass the cable

through one of

the ventilation holes on the A22 faceplate.

- Solder the coax

center

conductor to the transistor circuit on the add-on board. Leave the

shield unconnected at that end. Make sure the shield will not come in

contact with anything. I used heat shrink tubing to cover the exposed

shield.

The completed coaxial

connection is shown on the picture below.

I wrote the

source code in BoostC,

an

ANSI

C

compatible

language.

This

compiles

within

the

SourceBoost

IDE, a free programming environment. The Hex files required for

programming the PIC12F683 for the

various HP 3586 versions are also provided below.

Operation

After the modifications are performed and everything is assembled back

together, power up the unit. The SLM behavior should be exactly the

same as before when it performs its power up self-tests and when you

listen to radio signals. Use your best frequency

measurement technique to verify that the unit is right on expected

frequency and

that it does not drift as a function of temperature.

Again, this upgrade to the SLM has no impact to the built in frequency

and amplitude measurement capabilities. This mod only affects the

product detector, so the speaker audio and rear jack demodulated audio.

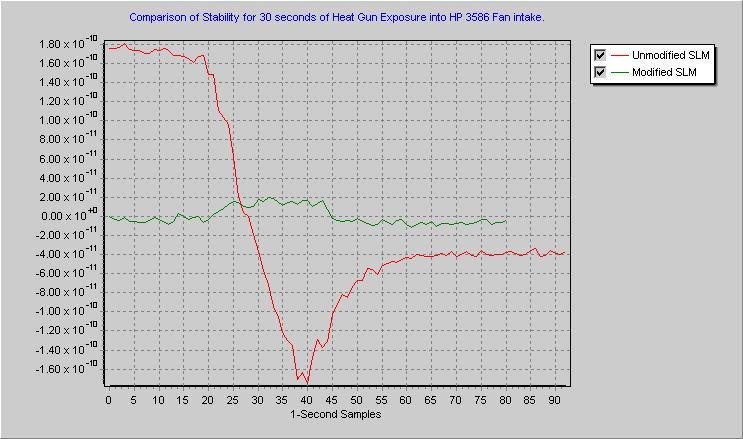

Stability

the main intent of this mod is to stabilize the SLM. The following plot

shows the drift of my HP 3586B before and

after the modification was applied. The heat up technique involves

blowing hot air into the rear air inlet (fan intake) for 30 seconds,

using a heat gun (paint stripper). The results speak for themselves...

Note:

the

small

step

on

the

green

curve

detected

during heat gun action is

unlikely temperature related. This could be an effect generated by the

heat gun motor brushes. The heat gun stood right next to the audio

cable going to the sound card.

Accuracy

The table below shows the delta in Hz - Targeted

vs.Resulting - after the modification is performed to the SLM. This

is the closest that the AD5932 can produce to the intended frequencies

with a 10MHz reference as the MCLK signal.

As can be seen, the delta is less than 0.3 Hz from any targeted LO

frequency. This same absolute delta in Hertz is applied to

any detected RF signal. So a 10.000MHz received radio signal would

have a detected audio frequency error of better than 3x10-8

or 0.03 ppm, assuming a LO

delta of better than 0.3 Hz. Actual error can be computed by doing

Error_Hz / RxFreq_Hz, using the delta numbers below. Since these are

known fixed deltas in frequency, this can be used to compute the exact

frequency of any audio tone or received RF carrier.

HP 3586 Single

Sideband (SSB) L0 Frequencies: Targeted and Resulting

|

| Model |

Opt. 003 |

Cal Active |

Sideband |

Targeted L0 Freq |

Resulting LO Freq

|

Freq Delta |

| 3586A/B |

YES |

NO |

USB |

17475Hz |

17474.88976Hz |

-0.11024Hz

|

| 3586A/B |

YES |

NO |

LSB |

13775Hz |

13775.22945Hz |

0.22945Hz |

| 3586A |

YES |

YES |

- |

16425Hz |

16425.25196Hz

|

0.25196Hz |

| 3586B |

YES |

YES |

- |

16625Hz |

16624.92752Hz |

-0.07248Hz |

| 3586A |

NO |

NO |

USB |

16975Hz |

16974.80679Hz |

-0.19321Hz

|

| 3586A |

NO |

NO |

LSB |

14275Hz |

14274.71638Hz |

-0.28362Hz |

| 3586B |

NO |

NO |

USB |

17125Hz |

17125.01049Hz |

0.01049Hz |

| 3586B |

NO |

NO |

LSB |

14125Hz |

14125.10872Hz |

0.10872Hz |

| 3586C |

- |

NO |

USB |

17475Hz |

17474.88976Hz |

-0.11024Hz |

| 3586C |

- |

NO |

LSB |

13775Hz |

13775.22945Hz |

0.22945Hz |

In the process of

developing this solution, I have learned a lot on DDS technology. This

was an iterative development. The following is a series of comments

that will explain why the final solution looks like this.

- Initially,

the

intent

was

to

use

the

MSBOUT

(Most

Significant

Bit) output pin as

the LO source. This would have been great since the output is

TTL-leveled, exactly what the SLM phase detector is designed to work

with. Unfortunately, this MSBOUT signal is not a clean square wave.

There is some phase jitter produced by the DDS engine every few

milliseconds, stretching the pulse repeatedly. This produced some

modulated noise on the audio. Rejected.

- So I switched to the sine wave

output. That output does not have the TTL amplitude swing provided to

the product detector by the original circuit. Analyzing the product

detector stage on the A21 plugin revealed that the 500mV

pk-pk max swing from the AD5932 VOUT would be sufficient to drive the

MC1496 product detector chip, as long as the

voltage dividing resistor on its LO input is bypassed.

So

a

small

jumper

wire

on

resistor R5 of A21 would be required.

- I was to run the DDS with a 100KHz TTL signal for the MCLK.

I obviously did not grasp much of the DDS theory. I tried this but the

output waveform was very distorted, with 6 (roughly 100/16.5) steps per

tone cycle. Very ugly and almost impossible to filter to a clean sine

wave. The sound was terrible. Rejected.

- I switched to a 1

MHz TTL signal for the MCLK, which is available right on A22. Though

the SSB audio performance had drastically improved with more than 60

steps per tone cycle, there were still audible spur

tones.

Since

these

were

within

the

audio

bandwidth,

it

was impossible

to filter out. Rejected.

- I finally settled

for 10MHz as the MCLK signal. It required the addition of the

transistor shaper stage, as nowhere in the SLM is there any continuous

10MHz TTL signal available. It is PECL logic world above 1MHz. But it

was worth it. With more than 600 steps per audio cycle, clean tones,

with no perceivable spurs. Only one simple capacitor as a low-pass

filter on the output. One other drawback of using 10MHz as the MCLK is

that we lose frequency selection granularity for the tone output. We

get accuracies of better than 0.3Hz (see table above). With 100KHz, it

would have yielded accuracies of better than 0.003 Hz. Like any design,

there were tradeoffs.

- Following this MCLK

rate change to 10MHz, returning to the MSBOUT TTL signal as the output

driving the product detector was attempted and it yielded a clean SSB

audio. The reason for this is that the phase-jitter-produced spurs

either fall outside the audio bandwidth of the receiver, or are low

enough in amplitude to not disturb a clean SSB detection. This is good

since the MSBOUT output swing replicates the driving LO amplitude

originally used on the SLM.

- Another choice of

DDS chip easily applicable to this project would have been the AD9833.

This

chip

has similar features, but has a 28-bit accumulator instead of

24 bits for the current AD5932. This would have improved the Targeted

vs. Resulting frequency deltas by a factor of 16. If reducing absolute

frequency error is your main objective, then you should consider the

AD9833. This chip has a different package though, and has totally

different configuration registers, so the PIC code provide above will

not work.

I would like to

thank Paul Swed WB8TSL, with whom I have

exchanged tons of emails during the development of this solution.

This development was done in sync between the two of us. Two brains

were better than one!

|

|