|

|

|

A Bluetooth Headset Interface with built-in

PTT for Amateur Radio

By: Bertrand

Zauhar, VE2ZAZ

Page last

updated: 02/02/2010

This

page presents an interface to a Bluetooth headset for

Amateur radio application. The key advantage

in my solution is that the

Bluetooth headset's answer/hang up push-button

can be used to control

the

radio PTT. This is very convenient inside and

around the shack.

The enforcement

of city and

provincial/state by-laws force the hams to

use a hands-free microphone

as replacement to the classic hand mike.

The Jabra A210 interface is the best

approach for add-on Bluetooth

capability to amateur radio transceivers. It

is sold as an interface

for

non-Bluetooth capable cell phones, but can

be quite easily adapted to

interface radio transceivers. The following

hyperlinks will give you

the background behind interfacing to ham

radio. I am very thankful to

those who did the early work:

In addition, here is the Jabra

A210

interface

instruction manual.

I

recommend that you consult the above links

before continuing on.

There is

one feature

in the Jabra A210 device that is not

documented anywhere and that has

not been proposed by anyone so far for PTT

support. It is the ability

for the A210 to pick up a cell phone call or

hang up using the

Bluetooth handset push-button. I have

discovered this after analyzing

the literature on wired headsets and on the

A210 itself. With proper

interfacing, this feature can be used for

wireless PTT support. In a

nutshell, the A210 sends a 400-millisecond

short to ground on the phone

plug tip every time the headset push-button is

depressed. This cannot

be sensed or perceived unless a weak pull-up

resistor is populated on

that signal.

In order for this feature to be used for PTT

support, a D-Type

Flip-Flop function must be added. Pressing

once engages the PTT,

pressing again dis-engages the PTT, and so on.

I have decided to

implement this function in a PIC

micro-controller. The PIC12F683 is a

low cost 8-pin device; this is smaller than

the 14-pin MC4013 dual

D-Flip-Flop chip. I also use an analog

function of the PIC, its

comparator input, for better noise immunity

and less loading on the

audio line. I have also added a timeout timer

that will release the PTT

if it is engaged for more than 2.5 minutes.

This could prove useful if

the bluetooth link is lost.

Since a 12V DC source is provided in a mobile

application, I have added

a +3.7 V DC voltage regulation that will work

with anything higher than

+7 V DC.

02/02/2010 -

Added notes

specific to West Carleton Amateur Radio Club

group project. Others may

disregard.

10/01/2010 - R5

value changed to

100K ohms. R7 and R8 value changed to 10 ohms

(easier to procure). Schematic

diagram (version 2) and

parts list updated accordingly. PIC firmware

updated to version 2. A few assembly

notes added.

10/01/2010 - R3

and R4 had their

value swapped on the schematic and on the

parts table. The PCB view and

PDF files have been updated.

05/01/2010 - Initial Release

My

Jabra A210 - Radio interface

schematic is shown on the right hand

side. The circuit is quite

straightforward. The headset microphone

audio

signal flows from left to right, from

the Jabra A210 to the radio

microphone input. A coupling capacitor

C1 is added to eliminate

possible DC contention on that line. The

headset earphone audio flows from right

to left, so from the radio

speaker to the A210 earphone input. I

have populated an optional

attenuator made of R3 and R4 to reduce

the audio level going into the

A210.

|

Click

on

the

figure

to

enlarge

it.

|

Note that the

speaker ground

and the headset microphone ground

are kept separate. Inside the Jabra A210,

there are separate pads on

the

PCB. This is to keep any ground loop (hum) to

minimum.

The pull up resistor that allows to produce

the pulse to ground is R5.

The pulse is detected by the PIC

micro-controller through R2. A wired

PTT push-button provides a local PTT

function identical to the headset

push-button. The PTT output sent to the

radio is provided by Q1, an NPN

open collector transistor. When the PTT is

active, the transistor

shorts the radio PTT line to ground. There

is also an optional PTT LED

line provided for visual acknowledgment of

the PTT state.

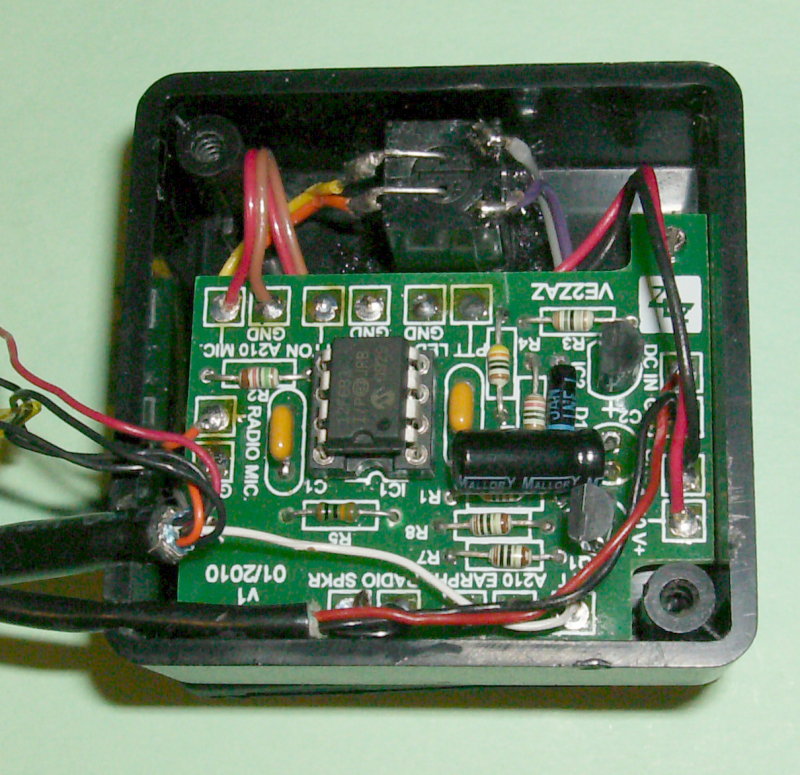

I have

created a PCB layout that

custom-fits a Hammond 1551RBK

enclosure. This

is a

neat and compact solution. The PCB

layout is shown on the picture to

the

right.

-

The PCB

is made of

single-sided copper clad

glass-epoxy material of 0.062"

thickness.

-

The

copper

pattern resides on the PCB

bottom side. The components

are located on

the top side.

-

When

hand-making the

PCB, drilling of

holes is required to solder

the components to the copper

pattern.

|

Click

on

the

figure

to

enlarge

it.

|

If

you wish to make this PCB yourself, here is

the PCB copper layout

file. It prints on letter-size paper. When

printing in full size (no

scaling) the dimensions and proportions should

be accurate.

I wrote the PIC12F683 firmware in ANSI C. I used

BoostC and the

BoostIDE environment. These are free compiler and

integrated design

environment available from SourceBoost

Technologies. The code is commented so that

you can understand what

is happening. Have a look at the .c file. Here is

the whole design

directory.

Some

preparation

is required in order to use the Jabra A210

Bluetooth

interface in my application.

- Open up the unit.

This is a delicate

task if you want to preserve the looks of your

A210. Using a sharp

knife, carefully crack open the casing. It is

easier to start on the

side where the casing has a long recessed

slot. Work your way to the

corners and the ends. Go gentle. The glue

should give pretty

easily. Watch out for the flying white button!

Work over a table and

make sure to recover the white button that

falls off when you spread

the two covers.

- Remove the old

battery. If you

intend to connect

the unit to the voltage regulator for external

battery operation or

12V DC, you

must disconnect and remove the old battery.

Simply cut off or desolder

the battery wires. There is hot-melt

glue on the contacts so take that off

first. The

battery is also glued to the casing; use a

small flat screwdriver

and gently

pull it off.

- Remove

the coiled signal cable.

Simply desolder or cut off the

four wires attached to the PCB.

There is

hot-melt glue on the contacts

and wires so take that off

first.

Preserve the rubber grommet to

plug the cable hole after

completion.

Simply cut off the

cable from the grommet with a

sharp knife.

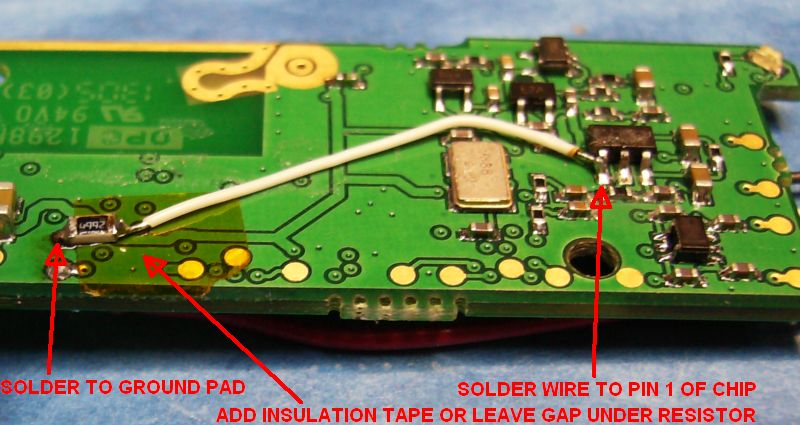

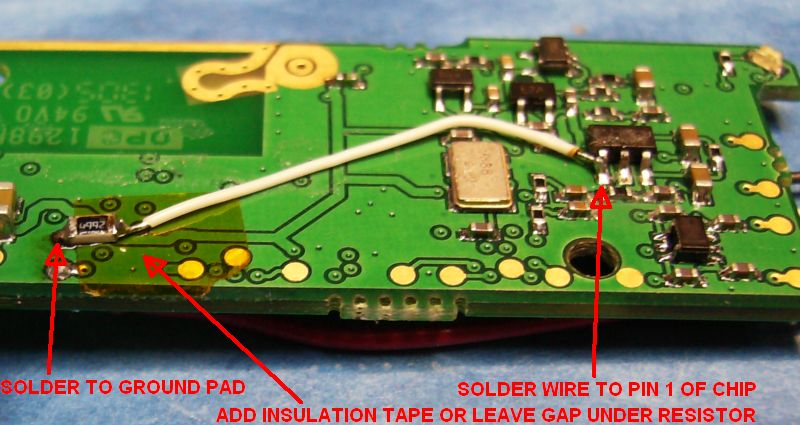

- Implement

VE3LC's

modification.

The

A210 normally transitions to a

power-saver mode after 60

seconds

without any audio fed into it.

For an amateur radio

application, we do

not want this. To keep it alive,

install a 47K resistor as shown

on

either of the pictures to the

right. I recommend using a

surface-mounted resistor. I used

an 0805-size resistor and some

AWG-30

"wire-wrap" wire. Implement the

solution you

are more comfortable with. In

either case, the result is a 47K

resistor

connected between pin one of

that chip and ground. If you are

still

unwilling to deal with

surface-mounted components,

implement VE3LC's

mod using a regular leaded

resistor as shown in his

PowerPoint

presentation.

|

Click

on

the

figure

to

enlarge

it.

Click

on

the

figure

to

enlarge

it.

|

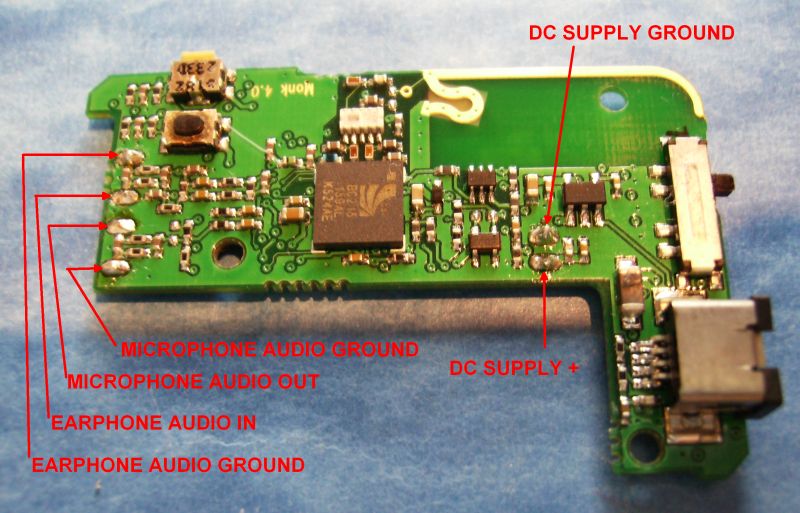

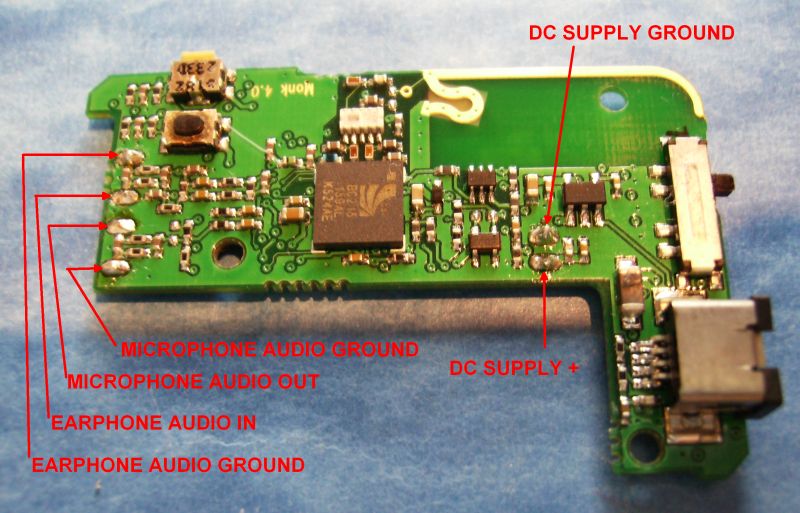

- Attach

new wiring.

Desolder any old pieces of wire from

the PCB and connect new wires to

the six PCB pads shown on the

picture to the

right. Use long enough wires to

allow interconnecting with the

interface PCB inside the Hammond

box. Using colored wires is a good

idea.

- Drill a hole in the A210 to

feed the wires

to the

Hammond enclosure. You

want to send all the wiring to the

Hammond enclosure located

underneath. Drill a hole through the

bottom

cover that is big

enough to accommodate all the new

wires. The best location is somewhere in the center of

the area where

the battery used to be located.

|

Click

on

the

figure

to

enlarge

it

|

PUTTING

EVERYTHING

TOGETHER

|

- Assemble the

interface PCB as per

the parts list provided below.

- I

highly

recommend

using an i.c. socket in the PIC

micro-controller location.

- The

PCB is quite small, so I had to keep the pad

size to minimum. This

makes re-work (replacing components)

difficult without damaging the

pads and traces. Make sure that the

components are in the right

locations before soldering!

- Depending

on

the electrolytic capacitor package used in

C2, it may or may not fit

in the proposed enclosure when mounted

vertically. Install C2 last and

bend its leads 90 degrees to mount it

horizontally (parallel to the PCB

surface), and above the other components.

- Install

the

PIC micro into its socket only after the

entire soldering process

is completed.

- Install

the momentary PTT push-button

and

the PTT LED (optional) on

the top face at one extremity of

the

Hammond enclosure. Make sure

that the PCB will still fit

inside the

enclosure with the proposed

push-button and LED locations.

See the

picture to

the right for the proposed

location. Note that I used a

push-button

with built-in LED.

- Drill

a hole to feed the wires from

the

A210 inside the enclosure. You

want this hole to be located on

the top face of the enclosure,

underneath the interface PCB.

Position

that hole to

align with the hole on the

bottom cover of the A210 so that

the A210 is

neatly positioned on top of the

enclosure. Use the

A210 bottom cover to mark the

location on the enclosure for an

exact

hole line up.

Once again see the picture on

the right

hand side for a suggested A210

location.

|

Click

on

the

figure

to

enlarge

it. Click

on

the

figure

to

enlarge

it.

|

- Drill a hole on

one side of the Hammond

enclosure to feed the DC power cable

and the radio speaker cable.

- Feed the A210

wires inside the enclosure.

- Attach the A210

to the top of the Hammond

enclosure. I used Coax-Seal putty.

Use something that can be easily

removed. Velcro is also fine.

Remember that the Bluetooth pairing pin-hole

is located on the bottom

cover of the A210!

- Install the

interface PCB. Bring

all the wiring underneath the PCB and above it

by routing it to one of

the open corners in the Hammond enclosure.

- Solder

the wires and cables to the

proper

locations.

Follow the wiring diagram shown

to the right. If you do it

right, you

should be able to take the PCB

out of the enclosure when all

the wiring is still attached.The

result should look similar to my

assembly shown below.

- Install

the proper connectors for the

radio

interface. Follow your

radio manufacturer's wiring

instructions

or the radio schematic diagrams

for the microphone connector

pinout.

|

Click

on

the

figure

to

enlarge

it.

|

|

|

VERIFICATION

AND

ADJUSTMENT

|

Make sure that

everything visually checks OK. Do

not connect the cables to the radio yet. Apply

power to the unit. Repeatedly press the

PTT push-button. The PTT LED should alternate

between on and off

states.

Press on the A210 power button until its blue

LED flashes a few time.

From that point on the A210 LED should flash

once every few seconds.

Now is the time to pair up the A210 and your

headset. Using a

needle-sized object, press the pairing button in

the hole under the

A210 casing. The blue LED should become solid

lit. Now put your headset

in pairing mode. This is usually done by

pressing the headset

push-button for about 10 seconds, but follow the

headset instruction

manual.

The pairing should be completed in about 20

seconds. This will be the

case when the A210 LED returns to a single flash

every few seconds. Now

turn off both the headset and the A210.

At this point, connect the radio speaker and the

microphone connector.

Go to an unused frequency on your transceiver.

If the SSB mode is

available, select it. This will reduce the RF

interference you produce

when the PTT is engaged.

Now turn the A210 back on. Then turn on the

headset. The radio should

transition to Transmit mode and the PTT LED will

turn on. This is

normal and inherent to the Jabra A210

push-button operation. Release

the

PTT by either pressing the headset push-button

once or pressing the

wired PTT

push-button on the Hammond enclosure.

As far as audio adjustments go, listen to an

occupied frequency and

increase the speaker volume on the radio. You

should hear the radio

speaker audio into the headset earpiece. For

transmit audio, you need

to monitor yourself into another receiver or ask

someone to help you.

There is a 3-position microphone slide switch on

the A210. Select the

switch position for best transmitted audio.

|

OPERATION

AND

PERFORMANCE

|

You are now

operating your Bluetooth headset on

Amateur Radio! There are a few things you need

to know when using your

headset on the air. Here they are:

- There

is

a

one-second

delay

between depressing the headset push-button

and

the radio PTT action occurring. This delay

is generated by the A210 and

there is nothing that can be done to reduce

it. In a typical simplex or

repeater

conversation, this is not much of a problem,

but forget about

contesting using the headset push-button! If

you need fast PTT action, just use

the wired PTT

push-button instead. Note

that the headset

microphone audio is always present at the

radio connector.

- Powering

up

the

Bluetooth

headset

will put the interface in transmit mode, the

LED will turn on

and so will the transmitter. Just remember

to quickly revert to receive

by pressing on the PTT push-button once.

Again, the A210 causes

this and nothing can be done to remove it...

- I have verified

that the

range is around 10m (30 feet) in line of

sight. Walls and floors will reduce the range

though. So I would not

claim

that you can walk around everywhere inside the

house and expect it to

work flawlessly. But "inside and around the

shack" is probably a better

way to

describe the range.

- I

have

noticed

that

there

may be a low-level constant-pitch whining

noise

present on the transmit audio. The intensity

of that noise seems to be

dependent on the headset type used. It is

quite low, certainly not

enough to annoy the people listening to you,

but it may show up.

Once

you

know these things, you can enjoy using your

bluetooth headset on

any amateur radio transceiver like I do in the

car. I actually like it

even better inside and around the shack. I can

walk around and still

provide

input on our local VHF SSB weekly net without

having to run to the

radio every time they turn it over to me. Very

convenient!

A210

Bluetooth - Amateur Radio interface Parts

List

(Version 2)

| Qty |

Designation |

Description |

| 2 |

C1, C3

|

1uF,

10V ceramic capacitor

|

| 1 |

C2 |

10uF, 25V electrolytic

capacitor, radial

|

| 1 |

D1

|

1N4148 or 1N914 silicon diode,

or equivalent silicon diode.

|

| 1 |

IC1

|

Microchip PIC12F683

micro-controller, DIP

package, programmed part.

|

| 1 |

IC2

|

LM317L voltage regulator,

TO-92 case

|

| 1 |

Q1

|

2N3904 or 2N2222 NPN

transistor, TO-92 case

|

| 1 |

R1

|

3 KOhm resistor, 1/4W axial

|

| 1 |

R2

|

15 KOhm resistor, 1/4W axial |

| 1 |

R3

|

180 Ohm

resistor, 1/4W axial |

| 1 |

R4

|

430 Ohm

resistor, 1/4W axial |

| 1 |

R5

|

100 KOhm

resistor, 1/4W axial |

| 1 |

R6

|

120 Ohm resistor, 1/4W axial |

| 2 |

R7,

R8

|

10 Ohm resistor,

1/4W axial |

| 1 |

-

|

Hammond 1551RBK

plastic enclosure |

1

|

-

|

LED, red color

suggested

|

1

|

-

|

SPST Momentary

push-button

|

Miscellaneous cables and

wires, radio

interface connectors, etc

|

| PCB, single-sided

copper clad glass-epoxy material of

0.062" thickness. |

|