|

|

|

A

12 Ghz Prescaler for The HP 5328A Frequency Counter

By: Bertrand

Zauhar, VE2ZAZ

Page last

updated:

21/03/2005

This

page presents an

add-on internal prescaler circuit for the HP 5328A frequency counter.

The Prescaler connects as a front-end to Channel C (520MHz) to provide

a frequency coverage from 100MHz

to more than 12GHz. Actual frequency is displayed,

not a divided ratio.

The

HP 5328A

Frequency Counter is a work horse. This is a well engineered 9-digit,

full featured counter with various options such as a DVM, frequency

extension to 520MHz or 1.3 GHz, ovenized TCXO and HP-IB (GPIB).

This counter is readily available on Ebay and in hamfest for less than

$100. These features make it attractive for various modifications.

Adding a microwave prescaler to this counter adds a lot of value to

the instrument. What makes this project feasible is availability of the

Hittite HMC363S8G. This is a

1GHz to 12GHz, divide-by-8 prescaler chip. The component's front end

provides a sensitivity that compares with commercially available

microwave counters. At the other end of the range, the chip can

tolerate input power of +13dBm. Its price is around $8 USD, which is

reasonable even for the hobbyist.

The

idea behind the prescaler implementation is the following: If you

divide down the input signal frequency by a factor N, and you divide

down the counter timebase (reference) frequency by the same ratio N,

the counter

will still read and display the right frequency. In other words, the

counter will count fewer input pulses by a factor N, but the sampling

window is expanded by the same amount N, yielding the same frequency

measurement. The only drawback to this technique is that the sampling

period required to obtain a specified resolution is lengthened by that

same factor N. This does not really constitute a problem in practice

though.

In the case of the HP 5328A, the

following criteria were taken into account when selecting the division

ratio N:

- The maximum frequency expected is 12-15GHz,

this limit

being set by current prescaler chip technology,

- The maximum frequency accepted by the existing

C channel

on the HP 5328A counter is 520MHz,

- The maximum frequency accepted by the A and B

channels is

125MHz,

- The desire to use only one model / one brand

of prescaler

chip to simplify ordering,

- Availability of the prescaler chip via

distributors,

A

compromise value of N=64 was selected. This is obviously achieveable by

using two instances of the same divide-by-8 prescaler chip model.

The

figure below shows how my prescaler

is

implemented in the HP 5328A counter.

It

consists of two or modifications:

- The addition of a front end Divide-by-64 RF

prescaler,

- The addition of a 10MHz divide-by-64 TTL

circuit which operates only when

Channel C is selected on the counter.

Note

that

the Prescaler modification

will also work on HP 5328A

counters equipped with the high stability reference TCXO option. As

well, the prescaler boards get installed in the locations normally

equipped by the DVM option boards. Thus, the DVM option is sacrificed

here.

The

Prescaler project is made of two main circuits (PCBs). The figures

below show the two schematic diagrams of these PCBs.

|

The RF Prescaler

Schematic Diagram

A MMIC

amplifier can be added between C4 to C11 to increase sensitivity. If

so, care

must be taken to avoid overloading U1, the first prescaler chip.

|

Click

on the

figure to

enlarge it.

|

|

The TTL Divider

Schematic Diagram

JP1, the 4x2

header, can be replaced with a simple wire jumper soldered in place.

|

Click

on the

figure to

enlarge |

|

The Prescaler board

layout

- This

PCB is made of double-sided copper clad glass-epoxy materal of 0.031"

thickness. This thickness is important to guarantee a 50 ohm impedance

on the high speed traces.

- The copper pattern resides

on the PCB top side along with the components.

- A solid copper ground plane

must be

present on the bottom side. The ground plane should cover the whole

surface except for the zone underneath the copper fingers at the

bottom. See the picture

below.

- Drilling of holes is

required in marked locations and are only for ground via connections.

- This PCB installs in the

5328A's slot XA7.

|

Click

on the

figure to

enlarge it.

|

|

The TTL Divider

board layout

-

This PCB is

made of single-sided copper clad glass-epoxy materal of

0.062" thickness.

-

This copper

pattern resides on the PCB bottom side. The components are located on

the top side.

-

Drilling of

holes is required to solder the components to the copper pattern.

-

This PCB

installs in the 5328A's slot XA5A.

|

Click

on the

figure to

enlarge it |

|

The

Channel C

Enable Signal Pickup board layout

- This PCB

is made of

single-sided copper clad glass-epoxy materal of 0.062"

thickness.

- This PCB

installs in

the

counter's XA5B slot.

It picks up the "Channel C Enable" signal.

|

Click

on the figure to enlarge it

|

If

you wish to make this project, here are the three PCB copper layout

files. These print on Letter-size paper. When printing in full size (no

scaling) the size and proportions should be accurate.

|

ADDITIONAL PCB

ASSEMBLY

INSTRUCTIONS

|

All

Boards

- All three PCB layouts have a

copper outline to mark the edges and ease the cutting process. These

copper outlines should be trimmed off, otherwise short circuits will

occur.

The

Prescaler

board

- This board uses surface-mounted

components. Only experienced

individuals should assemble

it. A

very fine soldering iron tip and a magnifying glass are required.

- Assembly should follow the

following order:

- SMA connectors,

- Ground vias, except for the 4

vias above and below each prescaler chip,

- All capacitors,

- The two prescaler chips (see

note below),

- Remaining ground vias near the

prescaler chips.

- When soldering the SMA connectors

to the pcb edge, ensure you keep the air gap between the connector and

the PCB edge to a minimum. Also, bridge the gap between the bottom

ground plane and the connector ground pins using plenty of solder.

- The two prescaler chips are

modified SOIC-8 package and have a ground pad on their bottom side.

These must be soldered to the PCB ground island first. To do so, apply

a thin amount of solder to the chip and a thin amount of solder to the

copper island. Do not overheat the chip. Drop the chip in place. Heat

up the PCB with the soldering iron as close as possible to the chip

while maintaining the latter in position. Then solder the eight pins.

- Solid pieces of AWG 20

or 22 wire should be inserted in marked locations to act as ground

vias. They should be soldered to both PCB sides and then cut flush with

the surfaces.

The

10MHz

Divider board

- Solder a piece

of wire

between

the Divider board's "Channel C Enable" pad and the longer finger on the

Channel C Enable Signal Pickup PCB.

- The

use of DIP IC sockets is

optional but recommended.

The

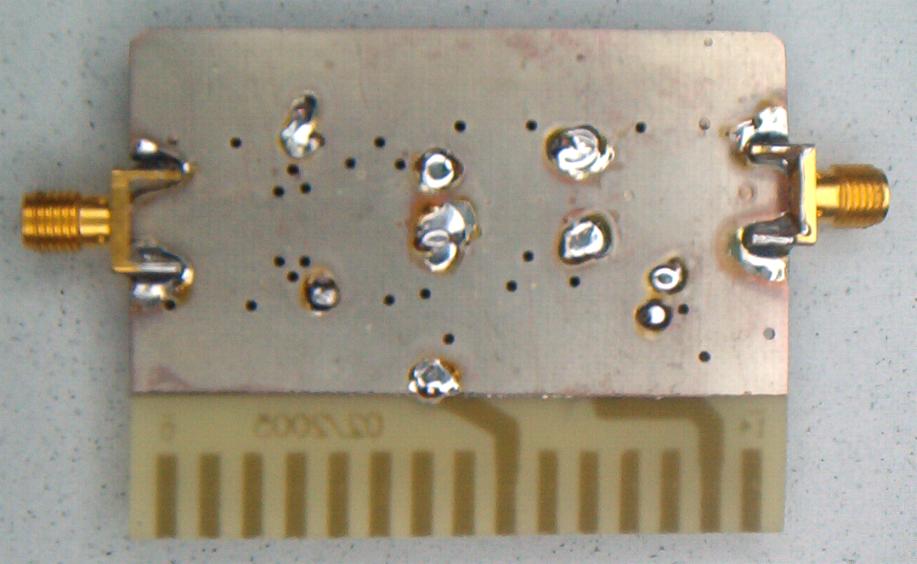

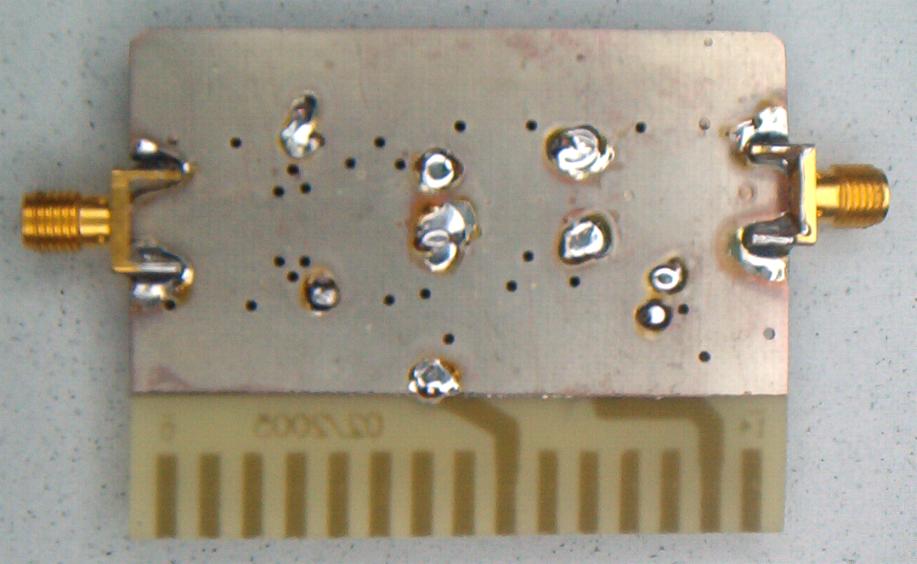

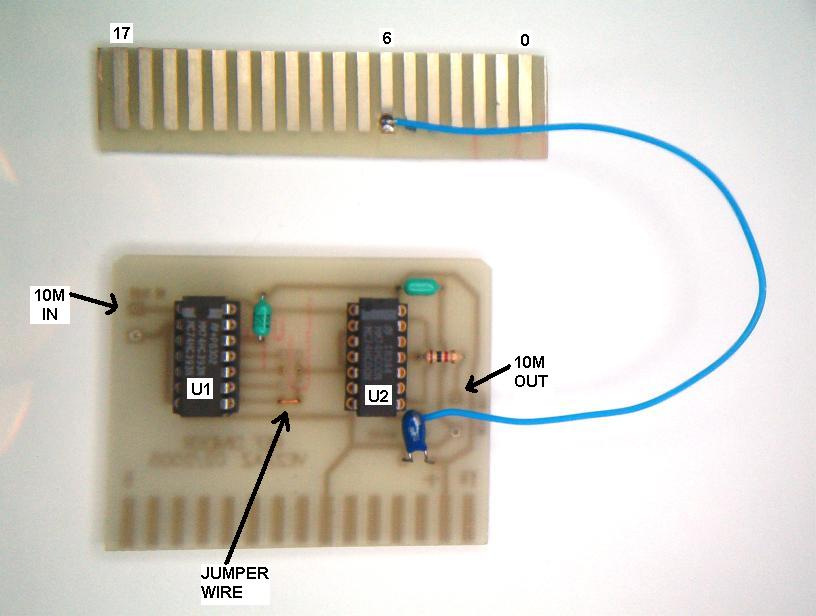

Prescaler PCB - Top View

(First Prototype) |

Click

on the

figure to

enlarge it.

|

The

Prescaler PCB - Bottom View

(First

Prototype) |

Click

on the

figure to

enlarge it. |

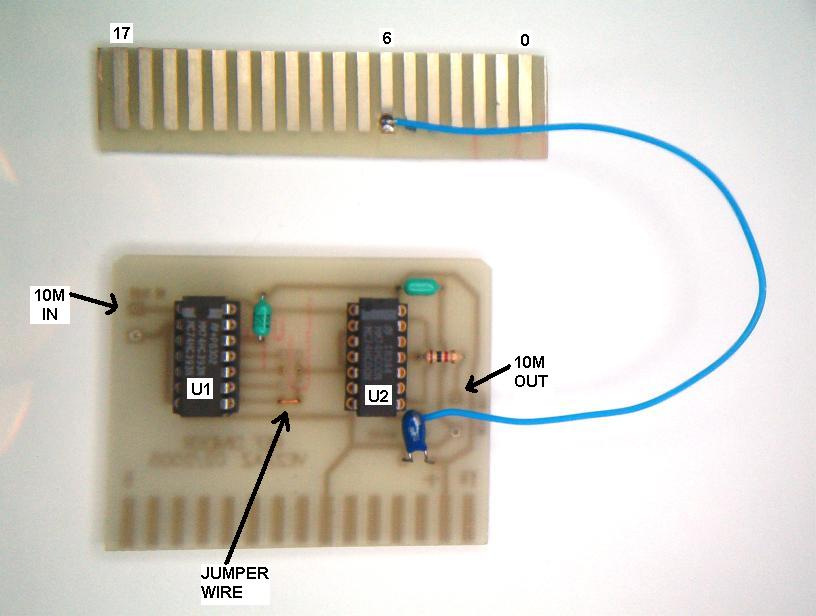

The

10MHz Divider PCB

and

The Channel C Enable

Signal Pickup PCB

(First Prototypes) |

Click

on the

figure to

enlarge it. |

INSTRUCTIONS FOR INTEGRATING INTO HP5328A COUNTER

|

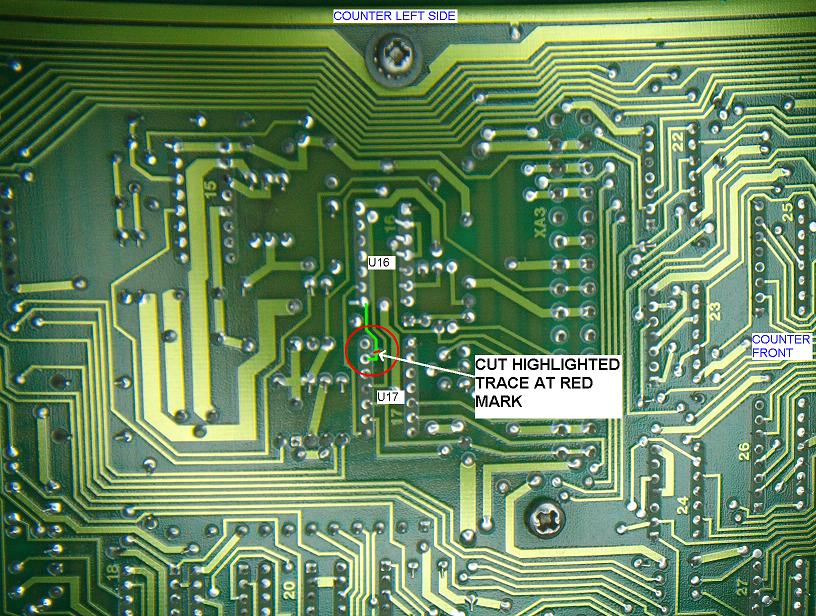

The

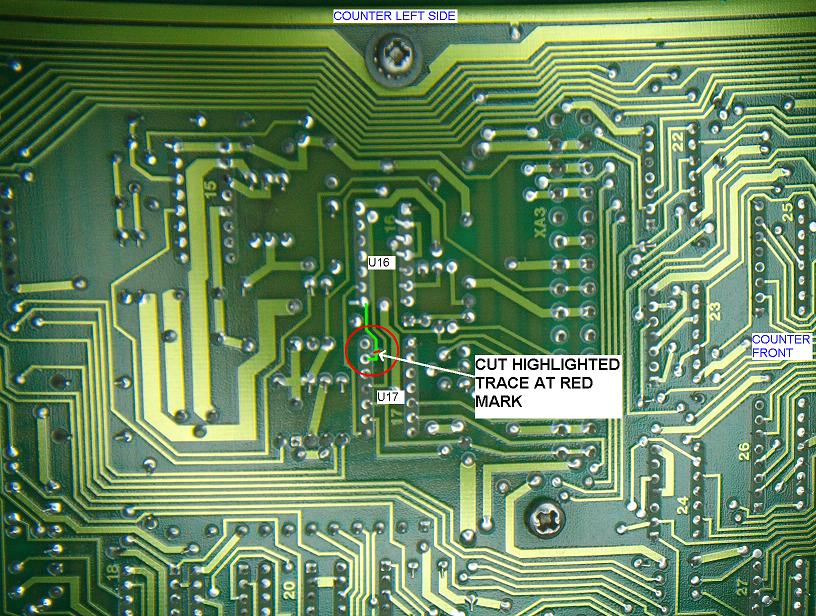

HP

5328A counter requires some

minor modifications in order to support the

new 10MHz divider circuit. One small copper trace must be cut to allow

insertion of the divider circuit into the chain. As well two coaxial

cables

are soldered to TTL chip pins. Follow these instructions:

Access

the botton side of the HP 5328A counter motherboard PCB in the 10MHz

reference area (rear-left area when seen from above the counter).

- Cut the trace that links

U16-pin8 to U17-pin13.

|

Click

on the

figure to

enlarge it. |

|

Access

the top

side of the HP 5328A

counter motherboard PCB, in the 10MHz reference area (rear-left area

when seen from above the counter). If the counter is equipped with the

HP-IB option, first unscrew the HP-IB board

(including the rear HP-IB connector and

lift the board. Disconnecting the board is not required.

-

Solder a

RG-174 coax cable to U16-pin8. Solder the other end of the coax cable

to the TTL Divider board 10MHz input pad.

-

Solder

another RG-174 coax cable to U17-pin1.

Solder the other end of

the coax cable to the TTL Divider board 10MHz output pad.

-

Only solder

the coax shields at the Divider PCB end. Ensure that the shields are

insulated at the counter's end.

-

If

necessary, re-install the HP-IB option board.

|

Click

on the

figure to

enlarge it. |

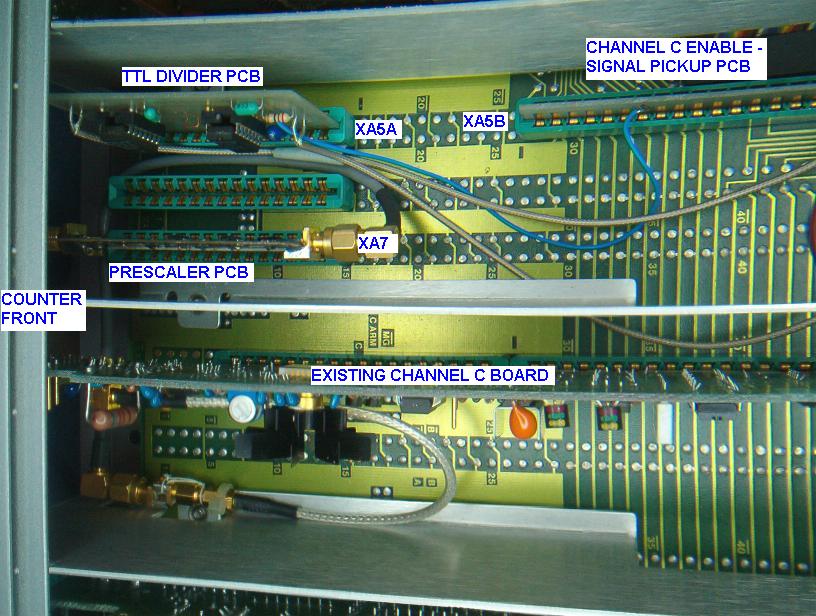

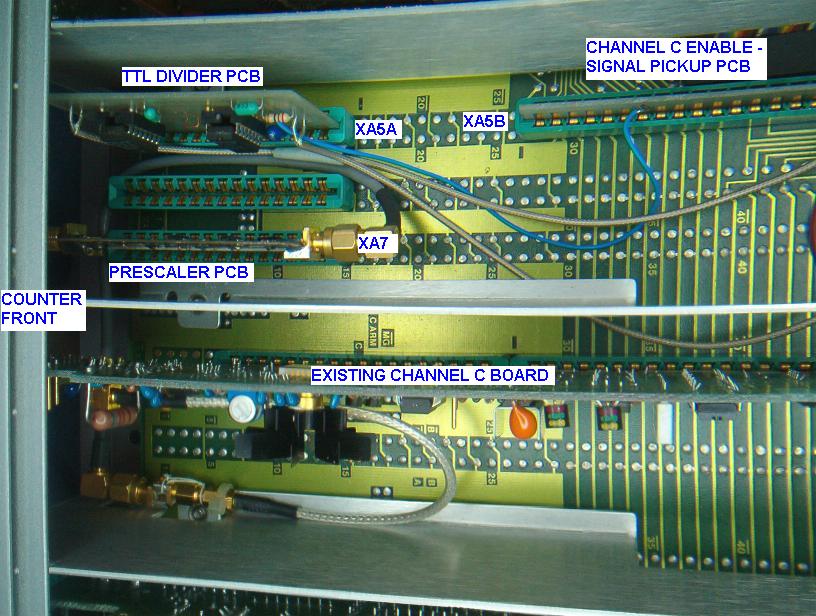

Now

is the

time to install the two PCBs

inside the counter. The prescaler fits in the locations where the DVM

options normally reside. If the counter is equipped with a DVM option,

you must first remove the PCBs that equip the left handside DVM option

slots, namely XA5A,XA5B,XA6 and XA7, and associated faceplate.

- Insert

the TTL

Divider

board in slot XA5A as shown in the picture. Components must face the

right handside when looking from the front of the counter.

- Insert

the Channel C Enable

signal pickup PCB in slot XA5B as shown in the picture. The copper

fingers

on the PCB must face the right handside of the counter when looking

from the front of the counter and finger 0 should be closest to the

front of the counter. The wire should come out near the top edge

of the PCB.

|

Click

on the figure to enlarge it.

|

- Insert

the Prescaler

board

in slot

XA7 as shown in the picture. Components and copper traces must face the

left handside when looking from the front of the counter. Since the

PCB in only 0.031" thick (half the thickness of a typical PCB, you must

also insert an insulated

shim of equivalent thickness on the back of the PCB finger area. A

piece of plastic or PCB material (copper removed) can be used.

- Connect

the Prescaler

RF

output SMA to the Existing Channel C input cable using a SMA-SMB coax

cable/adapter combination.

- Hook up the Prescaler Input

SMA to a RF connector previously installed on the faceplate.

|

Click

on the

figure to

enlarge it.

|

|

OPERATION AND

PERFORMANCE

|

If

everything visually checks OK ,

apply power to the counter. When selecting channel C with no signal

applied, you will see an erratic frequency display. This is

normal since the noise generated by the prescaler is enough to trigger

the Channel C gate. Apply a 0dBm, 1GHz RF signal. The counter

should display an accurate and consistent frequency. Try different

frequency and amplitude signals to verify proper opration.

Switch back to Channel A and apply a signal, for example 100MHz, to

input A. Verify proper operation.

The following plot shows the

operational range of the finished Prescaler. Between 1GHz and 12GHz,

sensitivity is better than -20dBm (22mV). The high end limit is set by

the maximum input tolerated by the prescaler MMIC chip, which is

+13dBm. The prescaler is usable up to 15GHz with reduced operational

amplitude range. This performance compares favorably with

commercially-made

units.

The

HP 5328A Prescaler Operational Range

|

Click

on the

figure to

enlarge it.

|

Table

1: 12GHz

Prescaler board Parts List (Version 1)

| Qty |

Designation |

Description |

| 1 |

C1 |

10uF,

10V surface-mounted Tantalum capacitor

|

| 10 |

C2-C11 |

10nF,

chip 0805 size capacitor

|

2

|

J1,

J2

|

SMA

connector,

PCB mount female.

|

| 2 |

U1,

U2

|

HMC363S8G,

12GHz,

Divide-by-8 MMIC prescaler chip, modified SO-8 package. Available from

Future-Active, (http://www.future-active.com)

|

| PCB

material, double-sided

copper clad glass-epoxy materal of 0.031" thickness. |

Table

2:

10MHz

Divider board Part List (Version 1)

| Qty |

Designation |

Description |

| 1 |

C1 |

10uF,

10V or higher , Electrolytic capacitor |

2

|

C2,

C3 |

100nF, 10V or higher, Ceramic capacitor |

1

|

JP1

|

Header

2

x 4, 0.1 inch pitch, OR short piece of wire

|

1

|

R1 |

33

ohm

1/4W axial resitor

|

| 1 |

U1 |

74HC393,

Dual 4 bit counter chip

|

1

|

U2 |

74HC00,

Quad NAND gate chip

|

2

|

-

|

DIP-14

pins

sockets (optional)

|

3

Feet of RG-174 coaxial cable

|

8

inches of hook up wire

|

| PCB

material, single-sided

copper clad glass-epoxy materal of 0.062" thickness. |

|